- Home

- Company

- air treatment

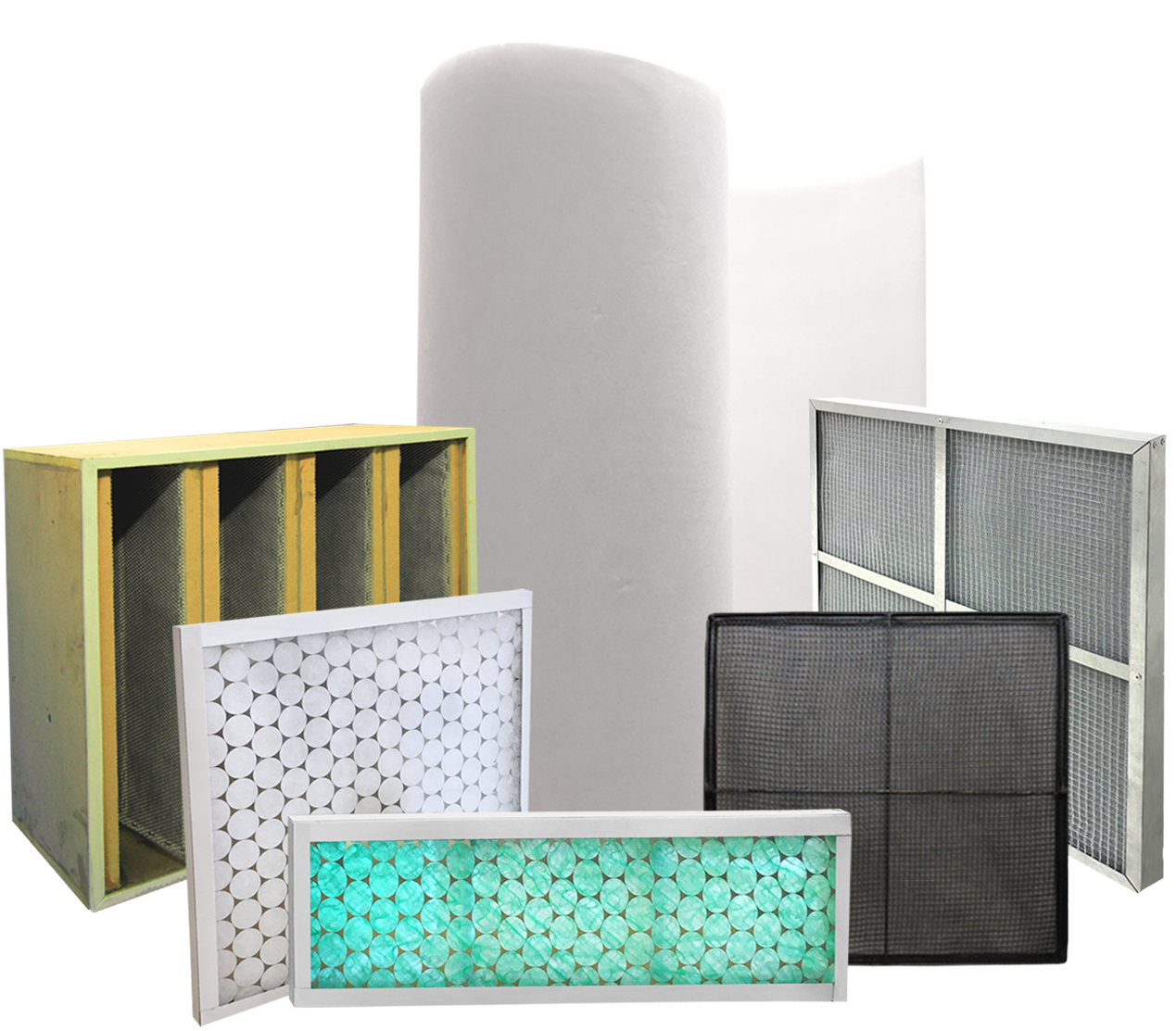

- Fiberglass Blanket

- Synthetic Fiber Blanket

- Activated Carbon Blanket

- Blanket Holder

- FGP Synthetic Blanket

- FGV Glass Blanket

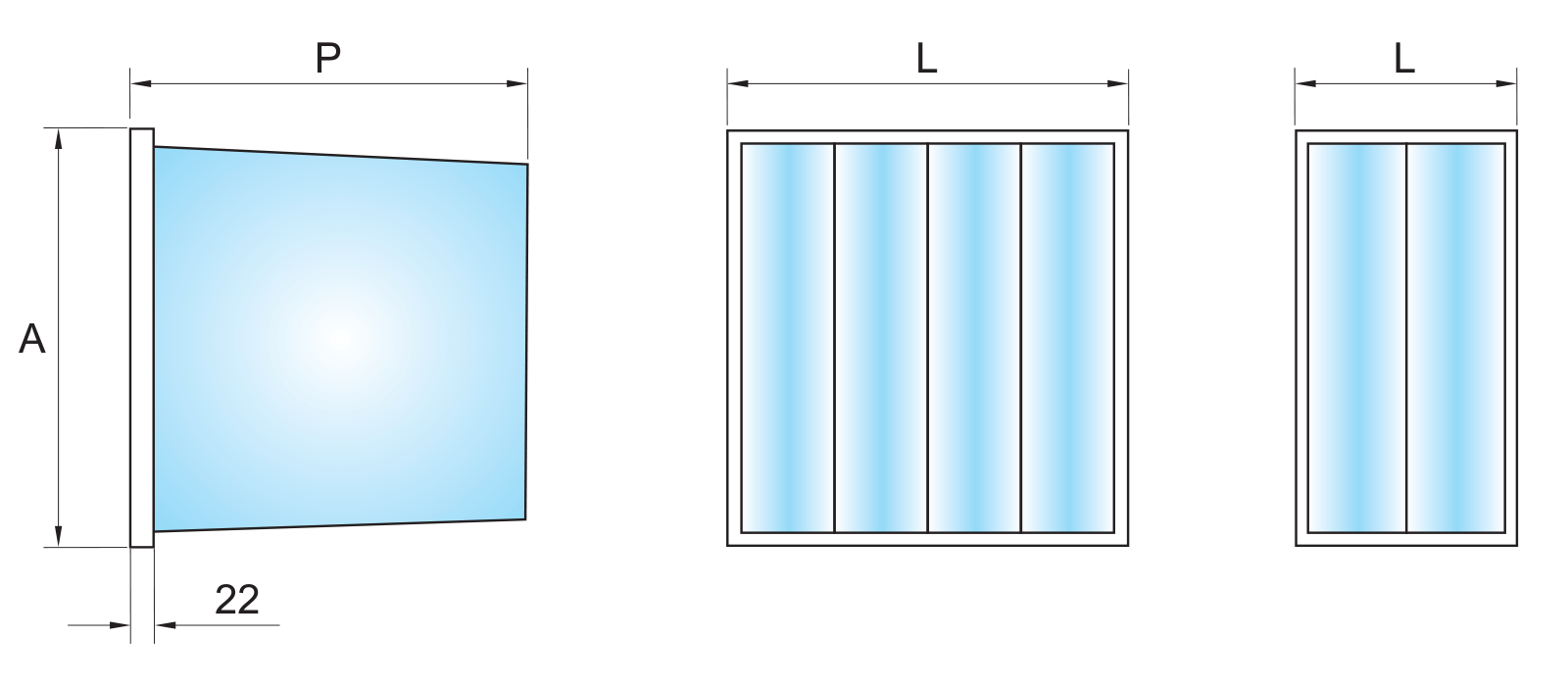

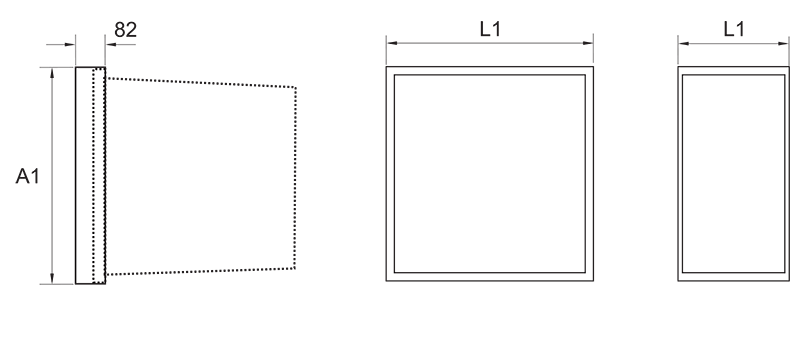

- ES and ES-E Flat Filters

- Flat ES/B and ES-E/B Filters

- SY-PL Flat Filters

- Metallic Filters

- Nylon Screen Filters

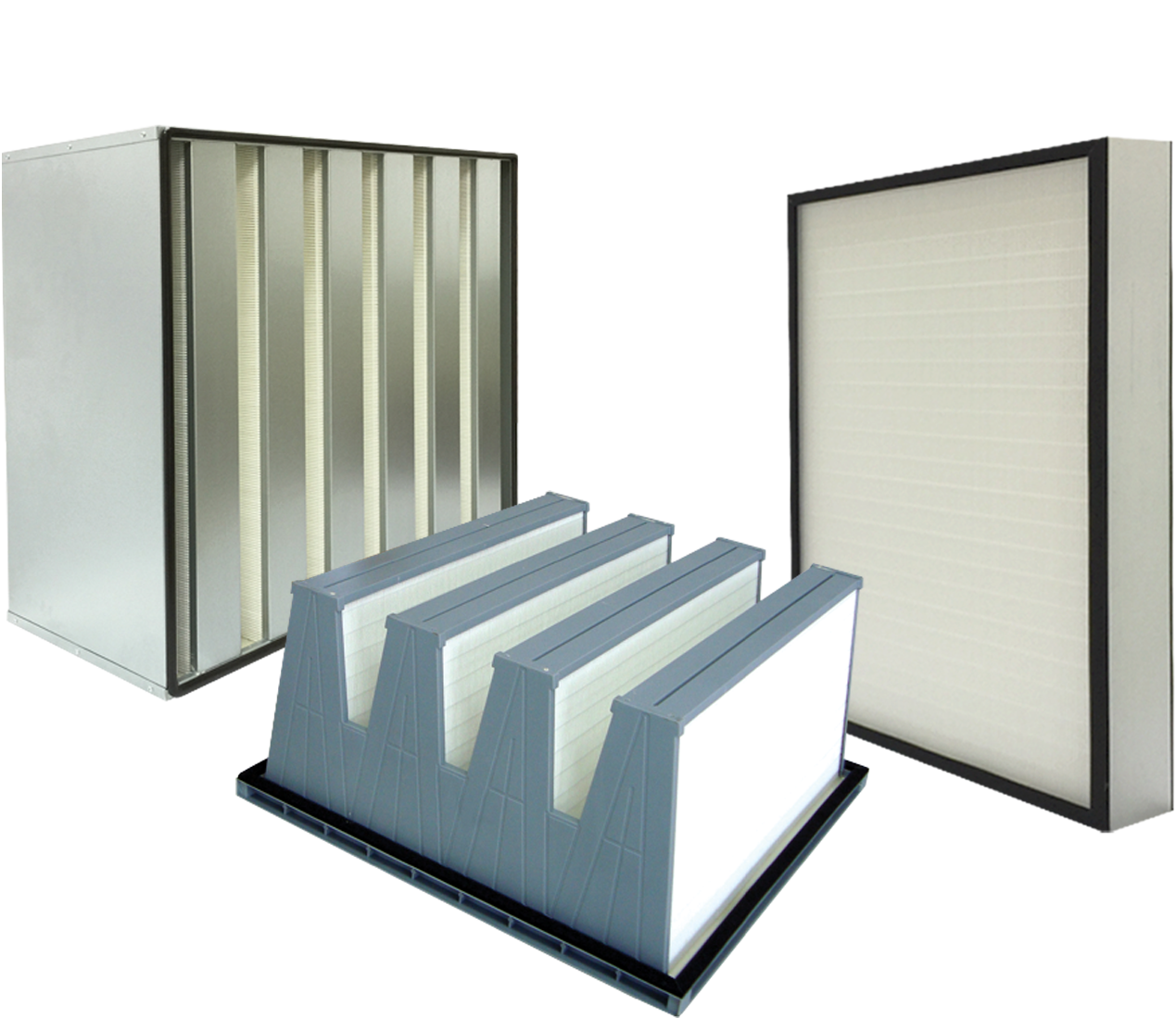

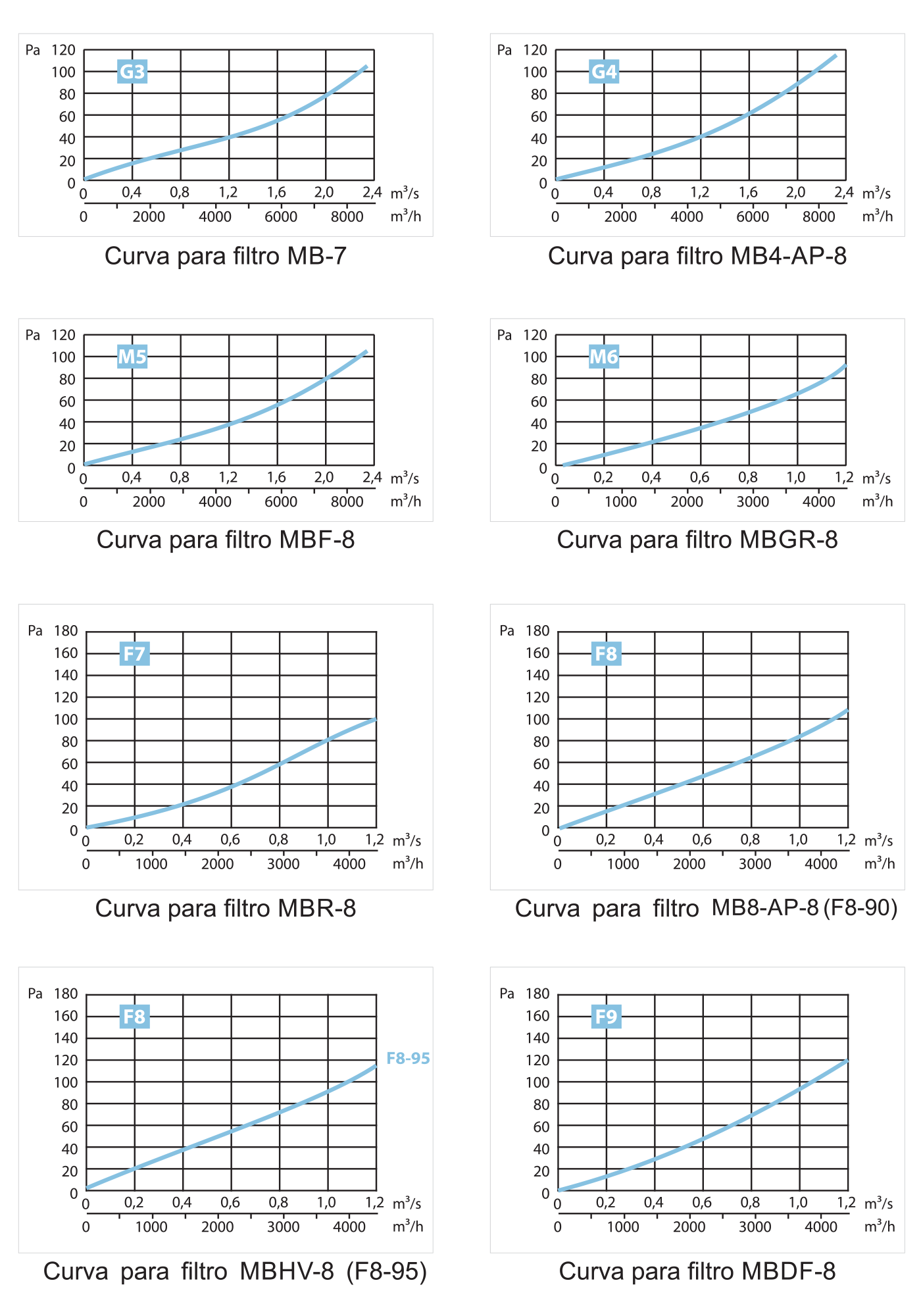

- FPP and IRP Fine Filters

- FP Fine Filters

- HEPA CRS filters

- HEPA filters N

- HEPA High Temperature

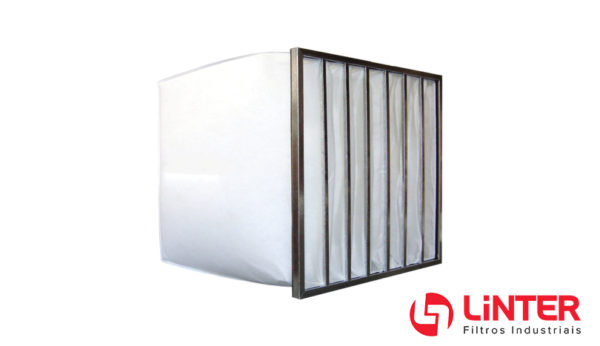

- Multi-purse filters

- Activated Carbon Filters

- Cartridge Filters

- pleated sleeve

- sleeves and cages

- Special Filters

- Nationalization

- Pleated Card

- Filters for Paint Booths

- Equipment

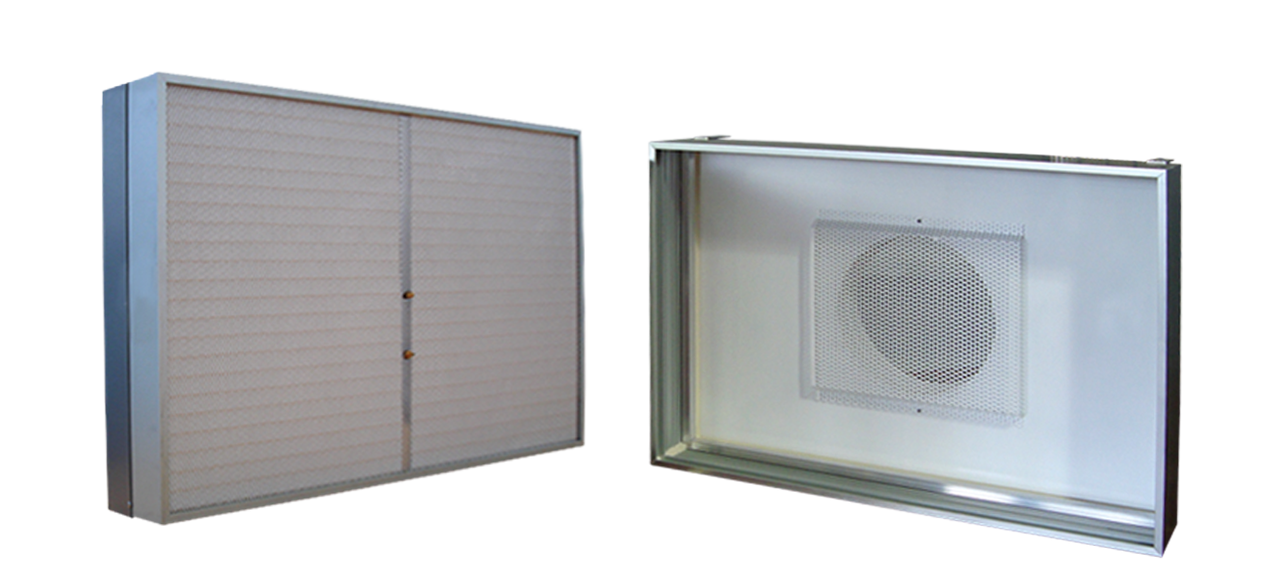

- Flat Panel

- Wedge Panel

- CQF box

- CQA box

- CMF box

- CRM box

- CRM Box + F

- Filtersept Terminal Box

- Fan Filter Unit GII

- UCFV - Filtration and Ventilation

- UDL - Air Decontamination Unit

- SDL-350 Digital Sequencer

- Solenoid Valve for Bag Filters

- “U” Column Pressure Gauge – MCU and MCU-P Series

- Standard Frame

- pressure gauges

- Water Filters

- plain polypropylene

- Grooved Polypropylene

- coiled polypropylene

- Carbon Block – Activated Carbon

- Drinking Fountain Cartridges

- Pleated Cartridges

- Refillable Cartridges

- Absolute Cartridges

- BAG Type Filter

- Membranes for Reverse Osmosis

- Carcasses / BIG BLUE

- Crepins - Distributor Drains

- Tanks in GRP

- Manual Valves and Automatic Heads

- Pressurizing Pump

- Chlorine Dosing Pump

- Filter beds and resins

- Applications

- Contact us