Air Filtration in the Pharmaceutical Industry

Ensuring quality in the manufacture of drug supplies is a key factor in ensuring that drugs fulfill their function. In Brazil, Pharmaceutical Industries follow strict standards in the manufacturing process of their products. They must comply with best practices and comply with the standards and requirements of regulatory agents.

The Brazilian Pharmaceutical Industry is considered an example of excellence anywhere in the world. This is mainly due to the quality of the raw materials used, good manufacturing practices, supplier assessment and the environment where the medicines are produced.

Regarding the production environment, we must highlight the air filtration system that, in addition to guaranteeing temperature and humidity control (preventing physicochemical and microbiological variations in its components), but also, non-contamination by microparticles and pathogenic agents. that can directly interfere with the effectiveness of the drug.

The air filtration system used in the pharmaceutical industries has the function of controlling the internal environmental conditions for the production of medicines, preservation of sensitive machinery and safety of professionals who are directly involved in the production processes, since the environment will be free of contaminants that can be harmful to health.

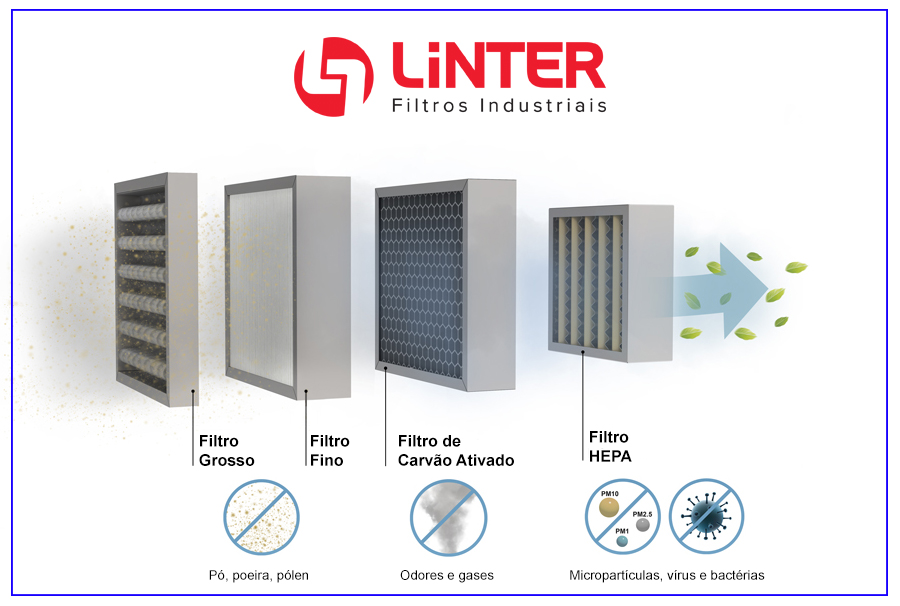

In HVAC systems (Heating, Ventilating and Air Conditioning, in Portuguese – Heating, Ventilation and Air Conditioning – HVAC, it refers to basic and primordial functions of air conditioning systems), the air purification process follows stages that are important for correct filtration, conservation, safety and longer filter life.

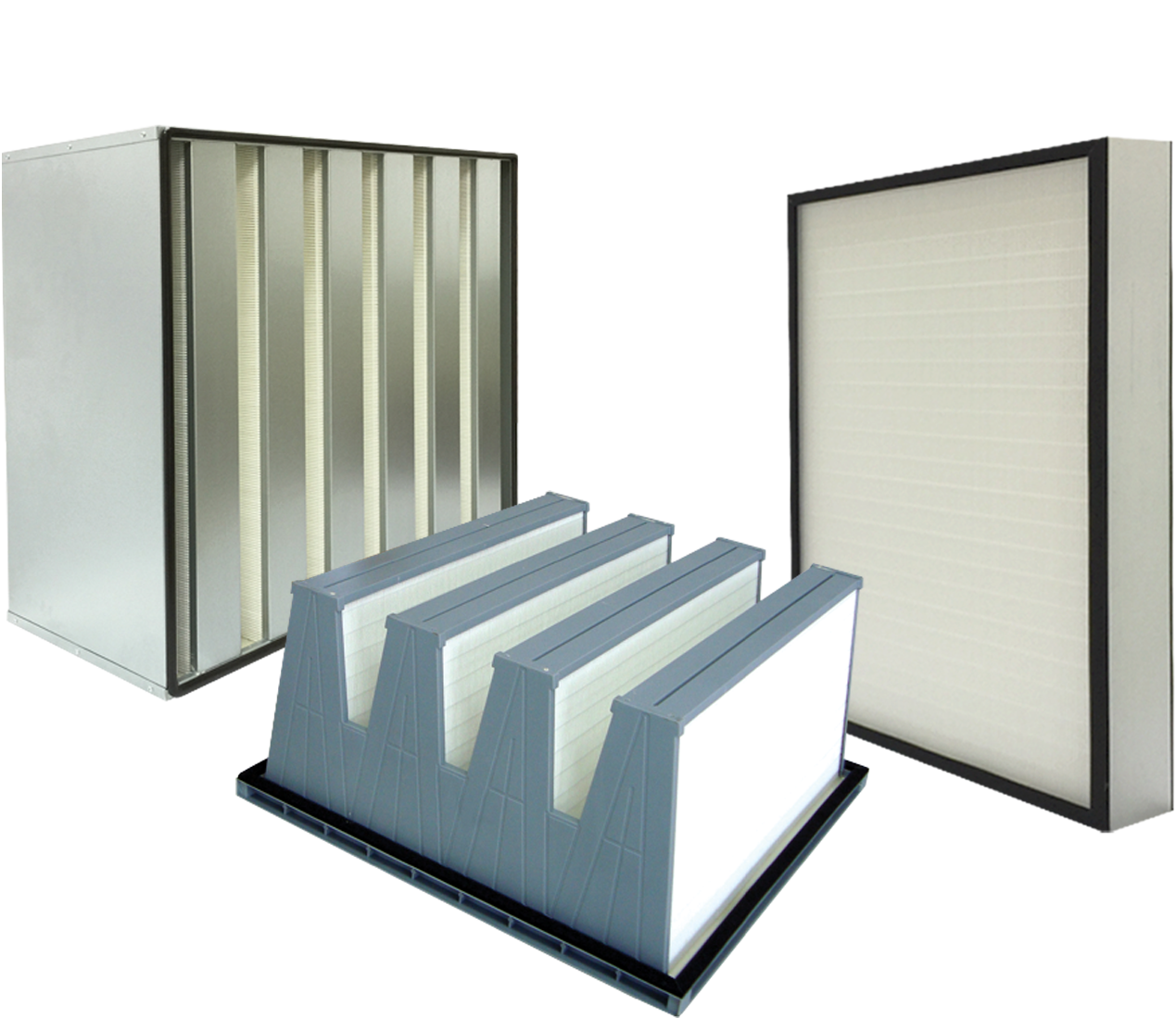

The main filtration stages of the systems are: pre-filters for coarse particulates, fine filters and HEPA (High Efficiency Particulate Air) absolute filters.

Whether in the Pharmaceutical Industry or in other sectors where we must obtain the maximum purity in the air, Hepa filters are the most indicated and used. Hepa Air Filters have high filtration efficiency for particulates that can measure below 0,3 µm, reaching very high levels of up to 99,95% retention. Undoubtedly, the Hepa Filter is essential for an efficient control of viruses and bacteria in controlled environments.

There are still situations in which we also use activated carbon filters for adsorption of gases and odors.

Therefore, the manufacture of medicines combined with an efficient air filtration system and its constant maintenance (change of air filters) of the system will guarantee higher quality and consequently greater confidence on the part of consumers, since the chemical composition of the products will not suffer no alterations or possible contamination.

Linter Filters is one of the largest manufacturers and suppliers of air filters for the pharmaceutical industry. With over 26 years of experience in the market, Linter Filters is present in the largest pharmaceutical companies in the country, offering quality filters at competitive prices and excellent delivery times.

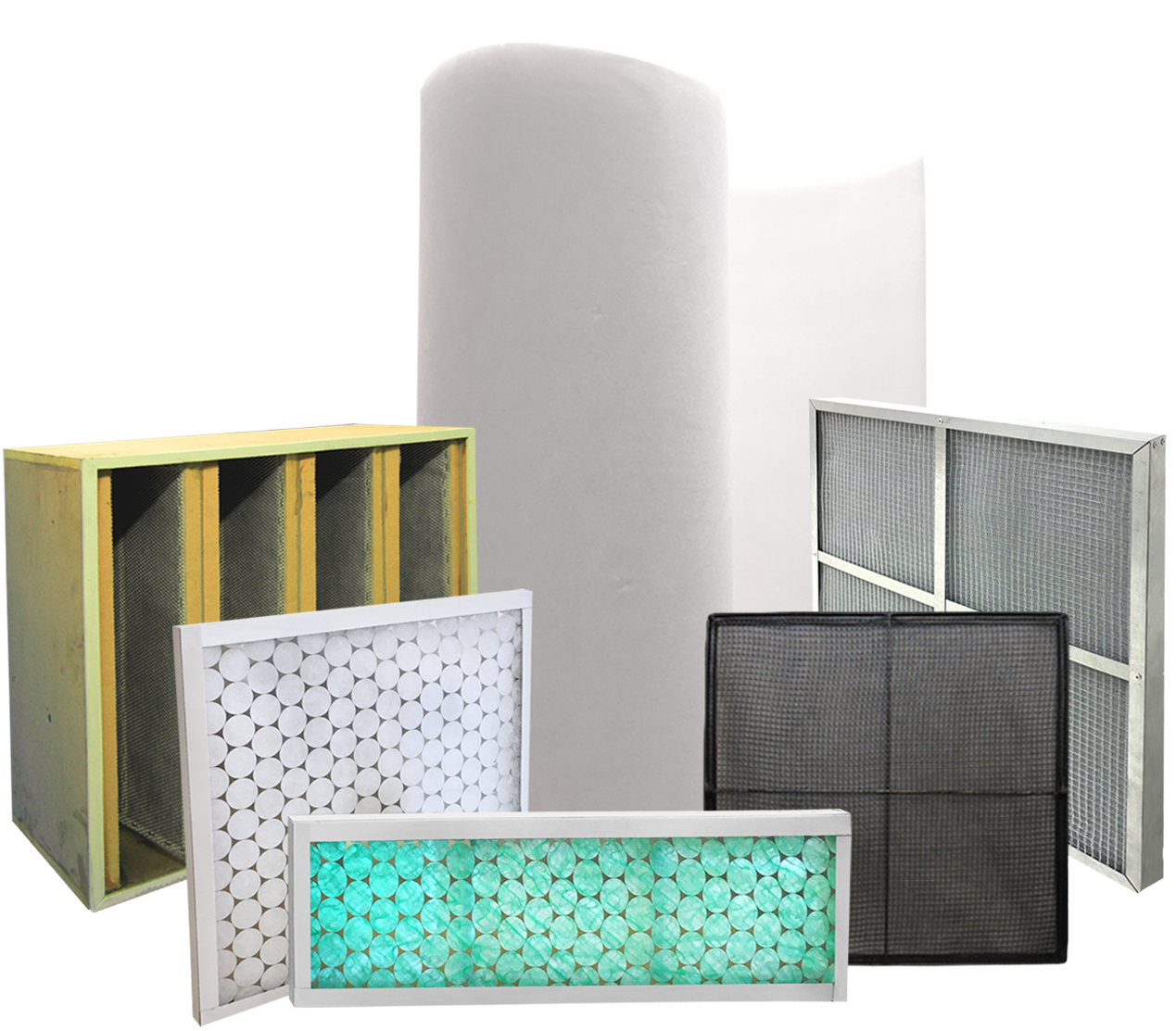

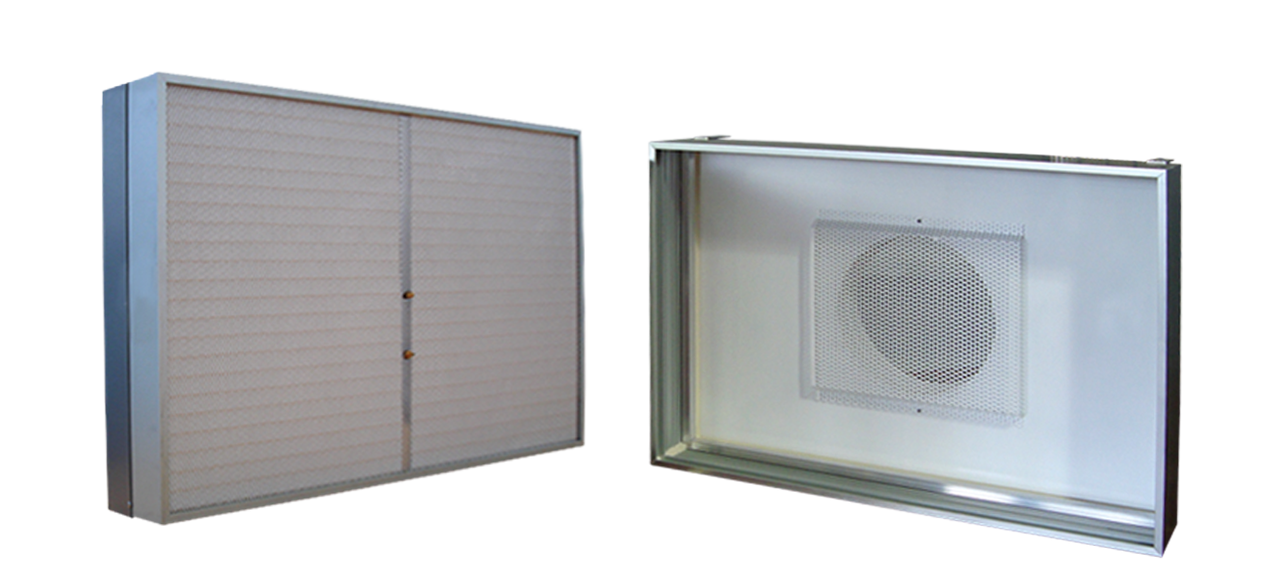

Linter also manufactures equipment for air treatment system. Filtering and ventilation boxes for ducts ou linings, filter panels, filtersept terminal box, Fan Filter Unit – GII e compact filtration and ventilation units, besides a complete line of accessories and filters for all filtering classes. See below the main filters manufactured by Linter:

- Air Filter Blankets

- Blanket Carrier Air Filters (Permanent Filters)

- Disposable Air Filters (Flat and Pleated)

- Multi-Bag Air Filters

- Fine Air Filters

- Absolute Air Filters - HEPA

- Activated Carbon Air Filters

- Special Air Filters

Click the button below 👇🏼 and get in touch with Linter Filters.

Hey! I want to talk.