A good air filtration system in hospitals prevents the environment from being a source of contamination for professionals, patients and companions. This is because hospitals are places with great circulation of people, especially those with some type of illness that can be transmitted directly through the air.

The higher the quality of the equipment used in the installation of air conditioning systems, the greater the chances of circulating clean air, with a minimum amount of viruses and bacteria.

The ABNT NBR 7256:2005 standard regulates the use of filters for air conditioning systems in hospitals. The main objective is to ensure the efficiency of air conditioning systems, establishing some parameters and requirements in establishments that provide health care to the population.

The main point of ABNT NBR 7256:2005 is to control how the installation of air conditioning systems in hospital environments will be carried out, check noise control, monitor the ideal temperature index, speed and relative humidity , in addition to the fact that the standard also establishes the need for periodic cleaning and maintenance. This contributes to everything being in order and operating correctly.

This standard establishes parameters and criteria that regulate the Law on the Maintenance, Operation and Control of Air Conditioning Systems, known as PMOC, enacted on January 05, 2018, which makes it mandatory to maintain air conditioning in collective, public and private buildings, in order to provide people in these environments with good air quality, minimizing possible risks caused by air impurities.

Controlling the level of air quality contributes to the safety of patients undergoing treatment. Research carried out revealed that the correct application of an air system, in hospital environments, directly contributes to the health of patients, drastically reducing cases of infections.

Below are the main environments that need an air filtration system:

- operating rooms

- ICUs

- isolation rooms

- Sterilized Materials Center (CME)

- Laboratories

- autopsy rooms

- postoperative rooms

- wards

- Reception and waiting rooms

Main air filters in hospital environments

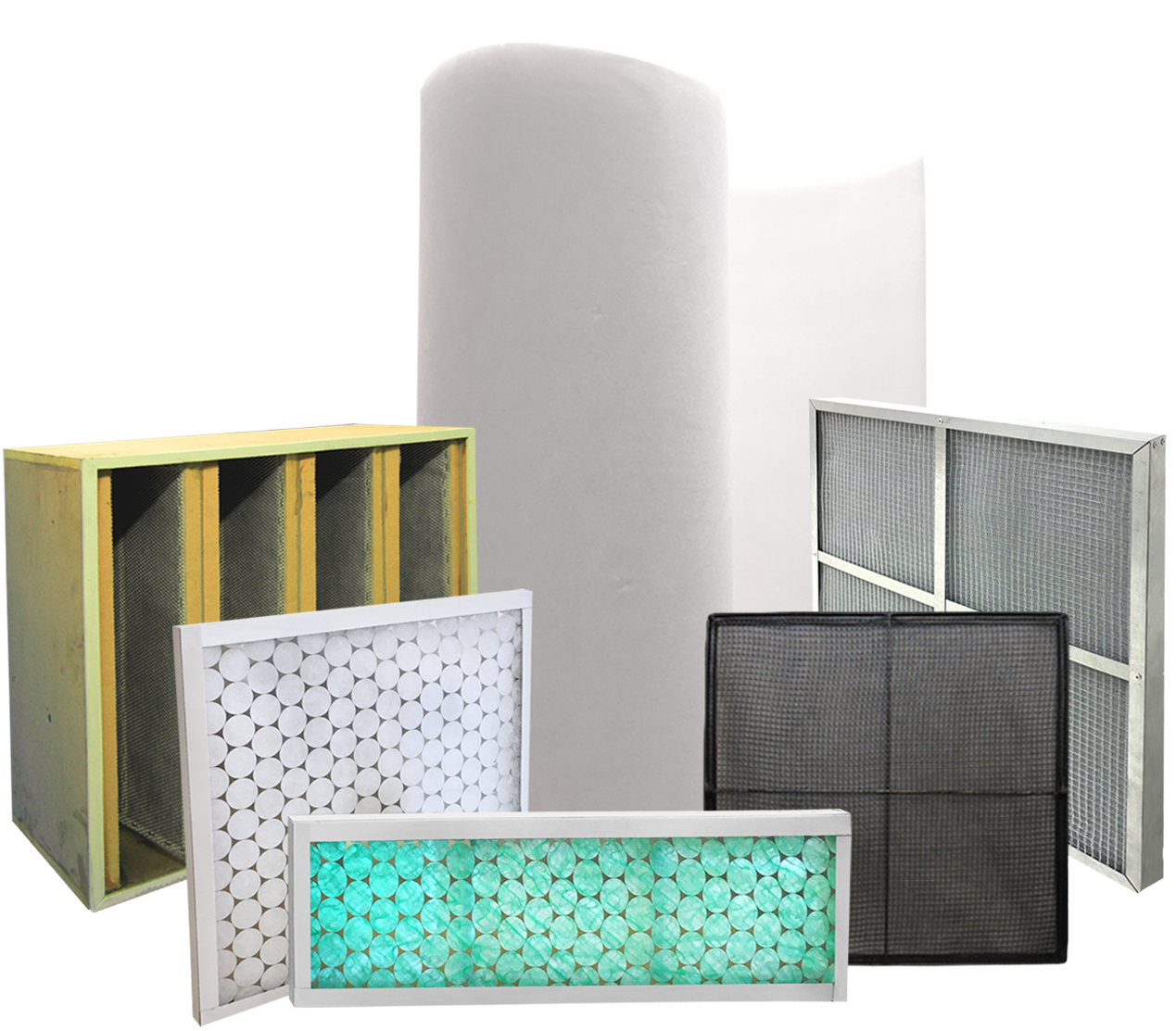

For a good filtration system, air filters are essential for the efficiency of these systems. Filters ensure that contaminating particles do not spread through the environment. The main filters used are:

Filters for coarse particles

We will highlight pleated filters – class G4/M5 (ABNT/EN779), synthetic pleated cardboard filters and medium efficiency filter mats.

Multi-purse filters

These filters are composed of inert, non-carcinogenic and non-toxic microfibers. They are arranged in such a way as to promote the progressive density of the fibers, gradually retaining the particles throughout the entire filter material, increasing the useful life of the filters and avoiding surface saturation. Filtering classes: G3, G4, M5, M6, F7, F8 and F9 (ABNT).

Fine Filters

Indicated in installations that need large volumes of filtered air, with low pressure drop, high capacity for fine particulate accumulation and longer durability. They have filtering classification F7, F8 and F9 (ABNT).

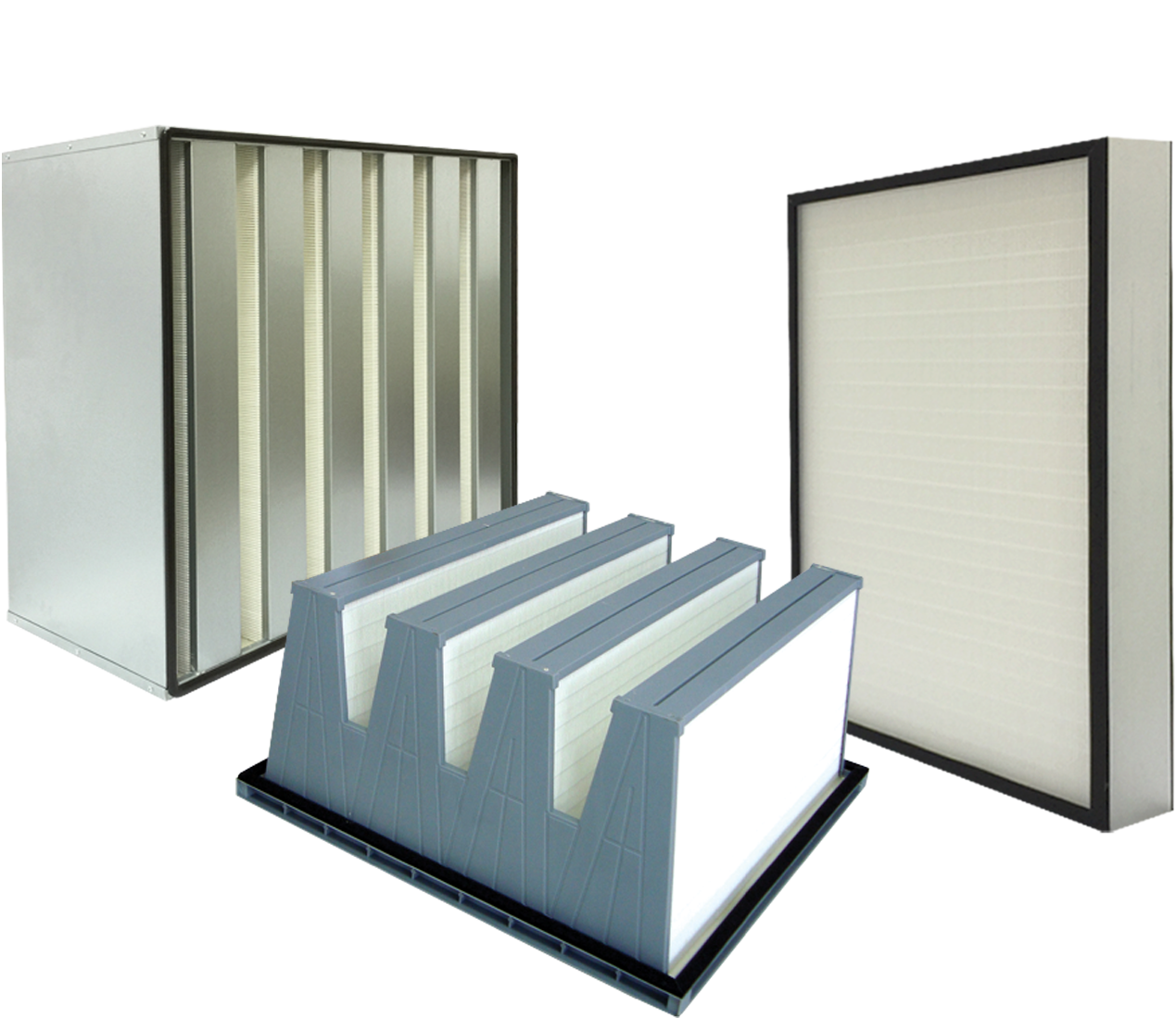

HEPA Absolute Filters

Hepa Filters (High Efficiency Particulate Air) have an efficiency above 99,95% for particles up to 0,3µ. They are used in situations where high levels of air purity are required. Operating rooms and ICUs are some examples of the quality that these filters can provide for these environments in hospitals.

Main Stages of Air Filtration

There are a few stages for using these filters, below are the main stages in a hospital HVAC system:

Stage 1 – A filter intended for pre-filtration is installed at the inlet of the air conditioner. In this case, you can use the disposable air filter, also known as coarse filter.

Stage 2 – Installed on the pressurized side. That is, after the fan. In this case, the pleated filter can be used, flat fine filter, Fmulti-pocket filter, among others;

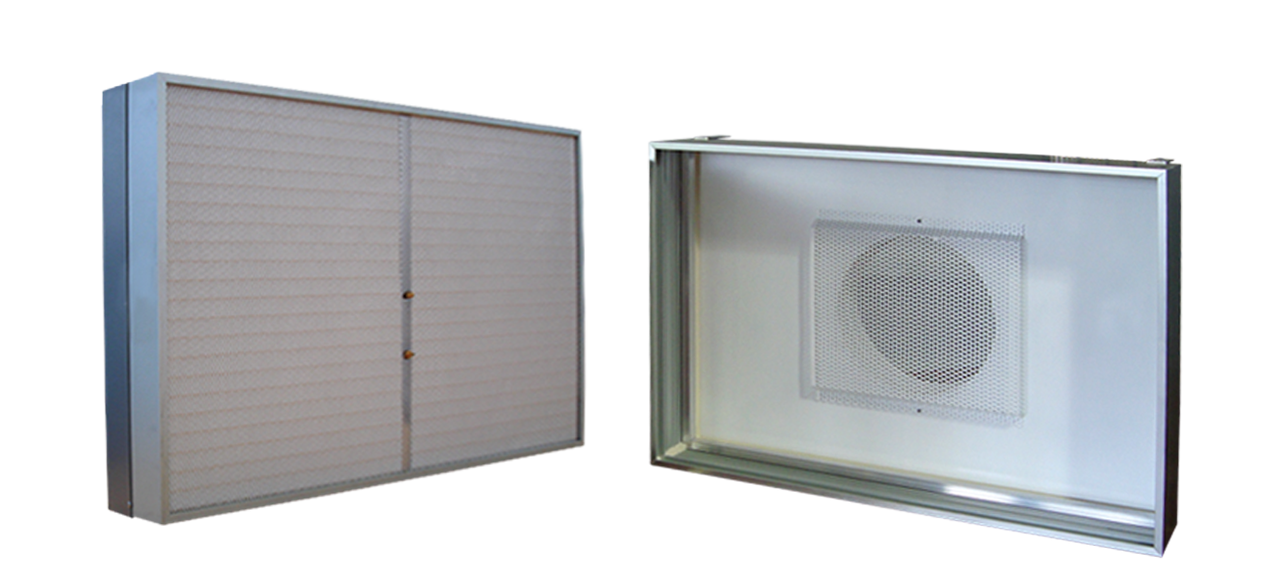

Stage 3 – Installed on the pressurized side of the duct, as close as possible to the treated environment, preferably at the insufflation terminal itself. The best option in this case is the use of absolute HEPA filter. It is important to note that equipment Fan Filter Units - FFU or unidirectional flow systems (laminar flow) are also recommended for operating room facilities, as patients are quite vulnerable during the procedures performed.

Linter Filters is one of the largest manufacturers of filters e air filtration equipment. With over 26 years of experience in the market, it serves hospital networks throughout Brazil. Linter manufactures thick air filters, medium air filters, fine air filters, multi-bag air filters, absolute air filters, special air filters and has in its portfolio a complete line of imported filters for hospitals and other applications.

Linter also manufactures equipment for air filtration such as ventilation and filtration boxes for ducts, ceilings, plenum in clean rooms, fan filter units, filtrasept terminal boxes, etc.

Click the button below 👇🏼 and get in touch with Linter Filters.

Hey! I want to talk.