HVAC System in Pharmaceutical Industries and Critical Areas

The technology of the HVAC system – heating; ventilation and air conditioning, is widely used mainly in places with large public circulation, such as shopping malls, theaters, restaurants, offices and industries of various segments.

The process carried out by this system is certainly responsible for bringing thermal comfort, renewal, treatment and indoor air quality to the environment. In addition to removing the moisture present, which facilitates the spread of fungi, bacteria and harmful particles.

Widely used in areas sensitive to contamination. The HVAC system in pharmaceutical industries is essential, as these are environments that need expanded protection at all stages of drug manufacturing, for their quality control.

In addition to the need to have clean and classified spaces, all processes must be carried out under an air filtering system, mainly aimed at protecting operators, the environment and products.

More than just a simple thermal comfort system. The HVAC system works with different pressure levels and air flow rates, in order to protect the entire operation. A failure in this system could cause contamination of the medicines, which would be discarded by the manufacturer's quality control, causing financial losses, as the medicines would be prevented from reaching the consumer market and thus causing damage to the health of the people who would use them.

In the industries of this segment the treatment of the air is a factor

safety critical!

Regulatory standards (ANVISA and ABNT) aim to protect and use good practices within these environments, from the manufacturing stage to the final packaging process. In conclusion, all these steps are susceptible to contamination. Therefore, the process of the air treatment system, above all, will minimize the risks present.

Air filtration through this system is done by capturing external air for renovation and pressurization of the environments, and the return air from the environments that then passes through several filtering stages through coarse, medium, fine and finally absolute filters. HEPA, which are mainly responsible for the air purification process, which is finally inflated into the environments.

The drug manufacturing process can also generate gases, which need to be treated and transported off-site through an exhaust system.

Know some of the benefits of the HVAC system in pharmaceutical industries:

- air filtration

- Renewal of ambient air

- Retention of dust particles

- Minimization of fungi and bacteria

- Thermal comfort

- Decrease in cases of allergic and respiratory diseases among local workers

Performing preventive maintenance of the HVAC system and changing the air filters are essential steps for the good efficiency of these systems.

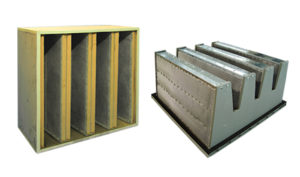

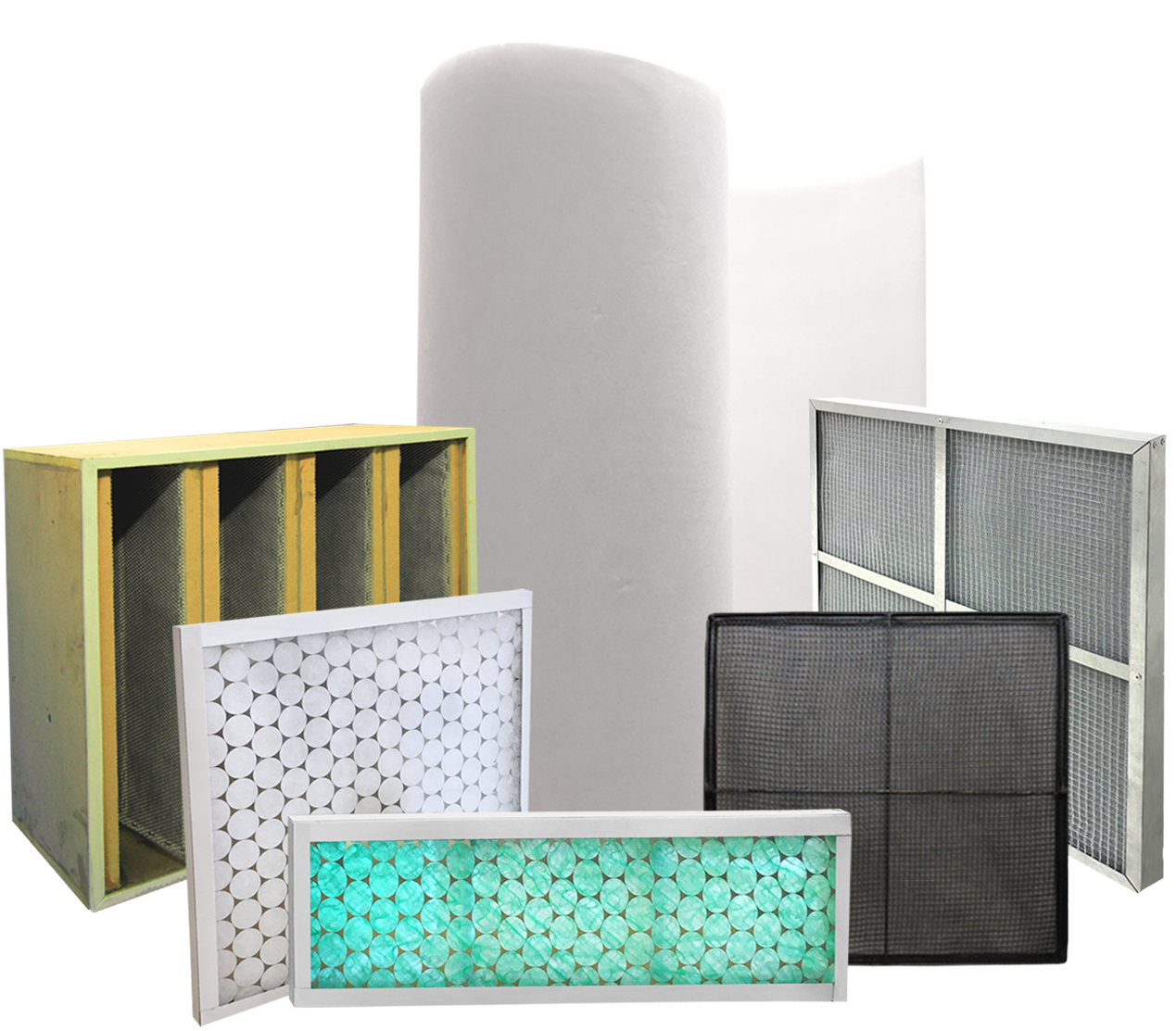

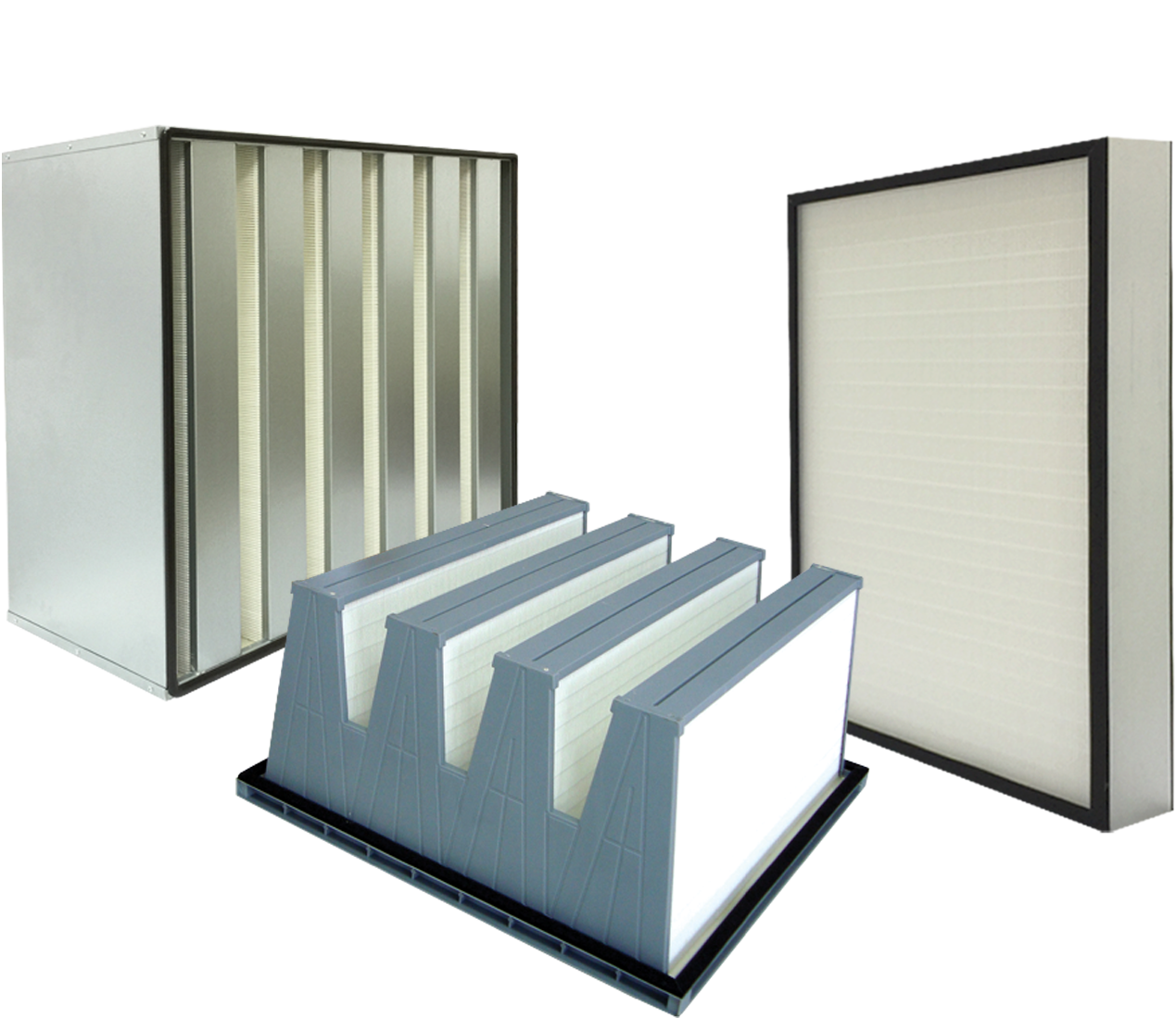

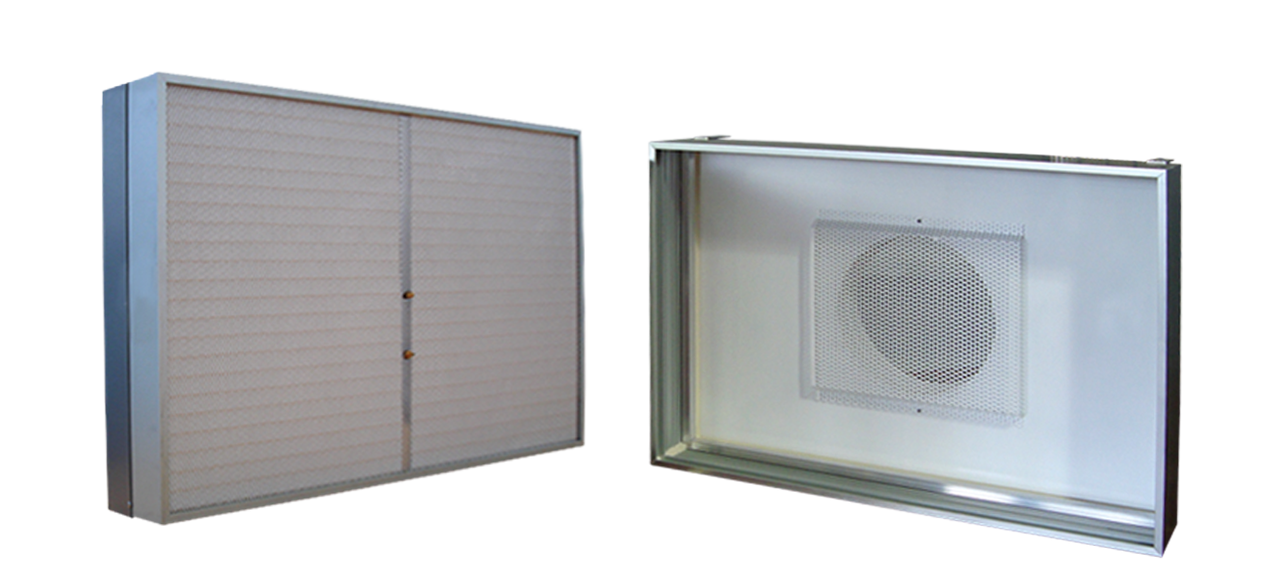

A Linter Filters manufactures a complete line of filters suitable for the HVAC System.

Discover some of the most used models below and request here a budget.

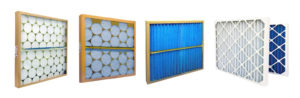

Blanket Filter

FilterDisposables

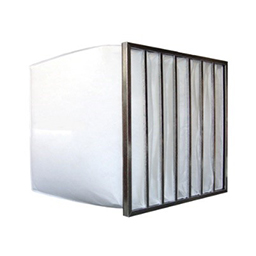

Multibag filters

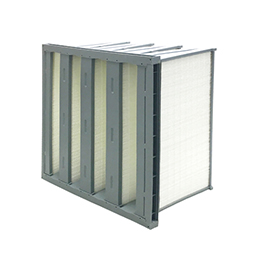

FP Fine Filter

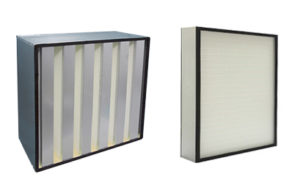

HEPA Absolute Filters

Activated Carbon Filters