Filtration can be a physical, biological or chemical operation that separates solid matter – and sometimes fluids – from a mixture with a filter medium that has a complex structure through which only certain elements of air (or fluid) can pass.

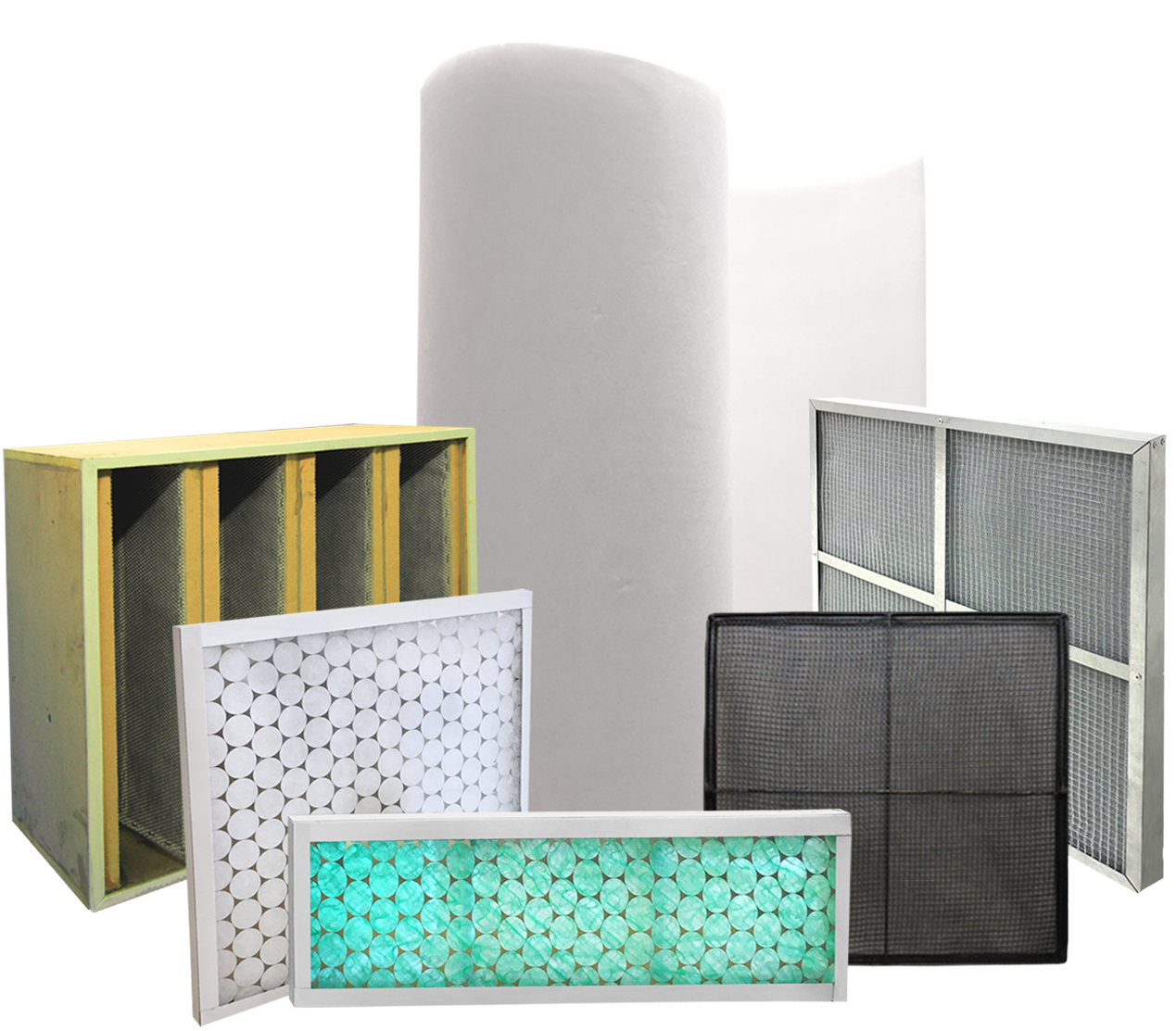

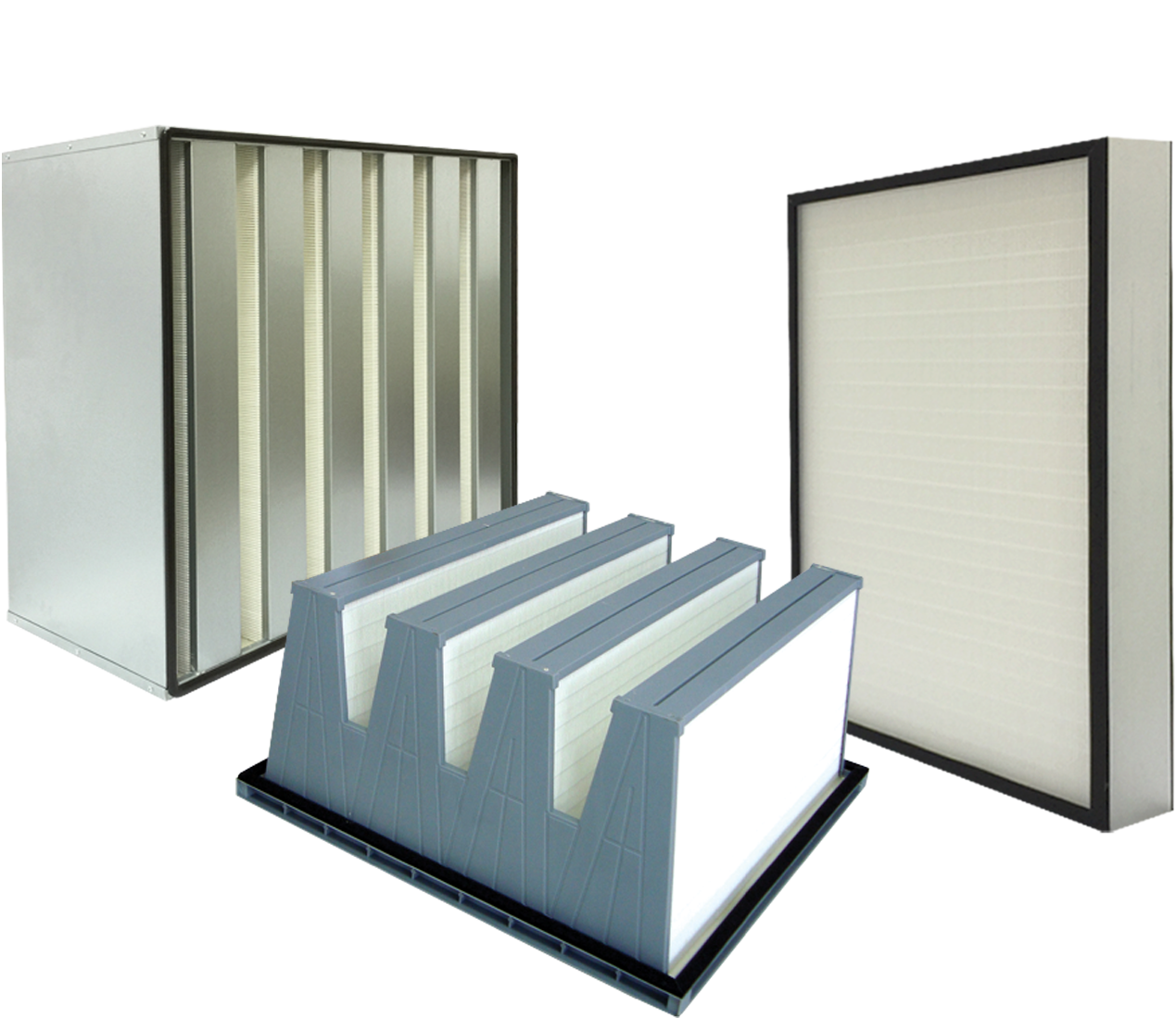

There are different types of HEPA filters to suit a range of applications, from the nuclear industry to pharmaceutical and semiconductor manufacturers. However, perhaps because of this variety, there is also a lot of confusion around defining the different types of filters available.

A HEPA filter is a type of mechanical air filter that works by forcing air through a fine mesh that traps harmful particles. Developed in the early 1950s, its original intent was to capture contaminants associated with the manufacture of the atomic bomb. In the beginning it was known as an absolute filter, because the objective was to have absolute efficiency, capturing any and all particles from the air.

Until the 1960s, the HEPA filter was not commercially viable. The change came when the use of HEPA filters were used in the production of transistors and in the semiconductor industry. It would be impossible to develop the sensitive electronics market without the use of controlled environments, especially with the use of clean rooms necessary for the manufacture of these components.

But cleanroom technology has not just been targeted by the microelectronics industry. Other sectors later benefited from HEPA filters for clean rooms, including pharmaceutical manufacturing, food and beverage production., and even to protect workers exposed to hazardous materials.

Understanding Clean Rooms

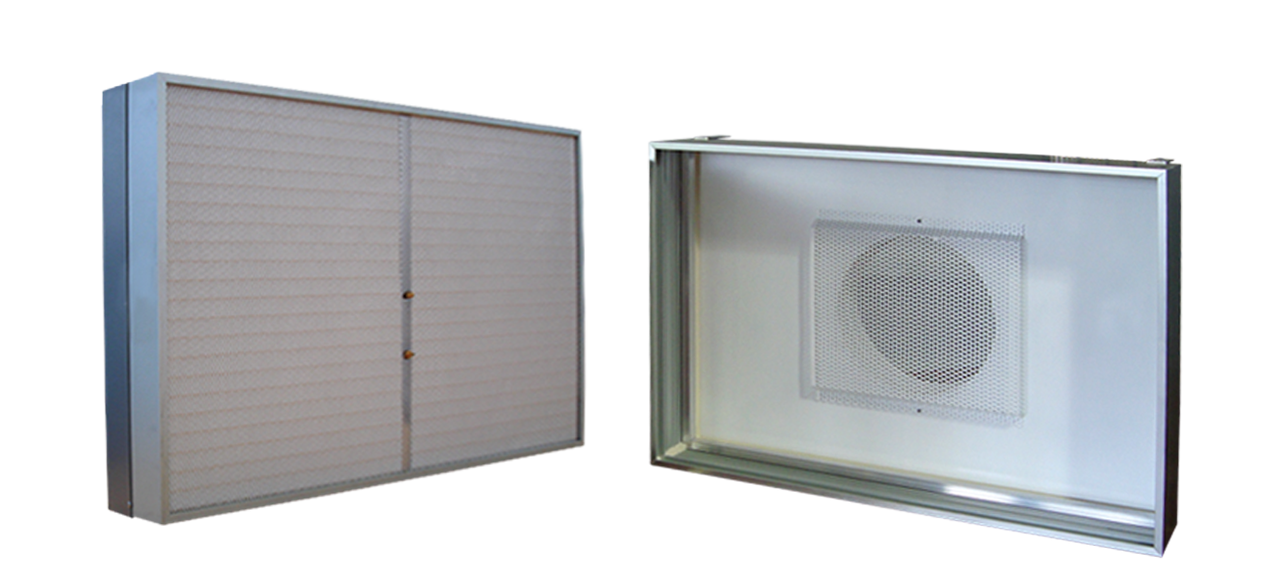

Hepa filters are normally installed on the ceiling of a room which is called a clean room or controlled environment. Some of these rooms have cleanliness levels that allow less than 1 particle per cubic meter of air. The average atmospheric air sample has tens of thousands of particles.

The pharmaceutical industry uses HEPA filters at an efficiency of 99,97% to 99,99% for particles down to 0,3µ. Their demand is not as stringent as the semiconductor industry, but they still employ cleanroom technology to protect the integrity of their products.

Filter manufacturing technology has improved and the cleaning requirements of product manufacturers have improved as well. Today, filter manufacturers have developed HEPA filters that have extraordinary efficiencies down to the level of 99,99995% at 0,12 micron.

Applications of Hepa Filters

Hepa filters are not only used in clean rooms, they can be applied elsewhere. Other applications of these filters include hospitals and medical facilities.

Typically used in ceiling or HVAC systems serving operating rooms, they protect the patient from infections, staff and visitors from airborne organisms. Recently, HEPA filters are being used in intensive care patient rooms (ICU and ICU), and of course in operating rooms and hospital wards that require greater air safety.

As a result, there was a significant reduction in mortality rates. According to scientific studies, fine particulate air pollution (PM 2,5) is one of the main risk factors for public health and air filters with high efficiency particulate filtration (HEPA) are a level intervention. promising to reduce these concentrations.

Below we list the main industries that benefit from the use of high efficiency filters:

- Hospitals;

- Laboratories;

- Clean Rooms;

- Pharmaceutical industries;

- Electronics and semiconductors industry;

- Food and beverage industry;

- Sterile unidirectional flow cabinets and modules, weighing cabinets and biological safety cabinets;

- Research centers;

HEPA filters have different configurations, including filters for high temperature applications, supporting temperatures up to 400 °C. These high temperature filters have the same efficiency as traditional Hepa filters and are ideal for vial sterilization tunnels, sterilization and depyrogenization ovens.

Linter Filters Industriais is specialized in Hepa Filters. We manufacture flat, wedge and high temperature Hepa filters. Access: https://linterfiltros.com.br/tratamento-de-ar/filtros-de-ar/filtros-hepa-absolutos/

A Linter Filters is one of the largest manufacturers of air filters and air filtration equipment. We manufacture Filtrasept Terminal Boxes, Boxes for Filter Ceilings or Plenum in Clean Rooms - CRM box e CRM Box + F, Fan Filter Unit GII (FFU) e Compact Ventilation and Filtration Units.

If you have any questions, we suggest you contact Linter Filters. Our engineers will detail better and indicate the best option for your company.

Click the button below 👇🏼 and contact Linter Filters.

Hey! I want to talk.