Filter Elements

Understand your role in industrial processes

The filter elements are the materials used inside the filters for Air or Water Treatment, used in the filtering process.

The role of filter elements in industrial processes is the retention of impurities and contaminants generated by these processes, as well as the retention of particulates that come from the environment itself.

Filter Elements for Air Treatment

The filter element is certainly the main item in the air filter, functioning as the heart of the filter!

In industrial processes, air filters perform, above all, the function of treating the ambient air, blocking airborne contaminants from the most diverse sectors of the industry, such as: dust particles, smoke, toxic substances and various particulates. The filters used will mainly ensure the health of people exposed to that workplace.

The choice of air filter to be used in this or that process will depend mainly on the filter element and the type of filtering that this element performs…

The main filter elements used e how they work...

Namely, there is a specific filter element suitable for each application in industrial processes, and what will differentiate the application is certainly the type of element contained in the filter, whether for odor attenuation, capture of microparticles, larger particles and so on. …

Within industries, more than one type of filter is generally used, and the combination of different filters with different filter elements is what will guarantee a good performance of the filtering system and air treatment, as a result there will be cleaner and safer air for the environment. .

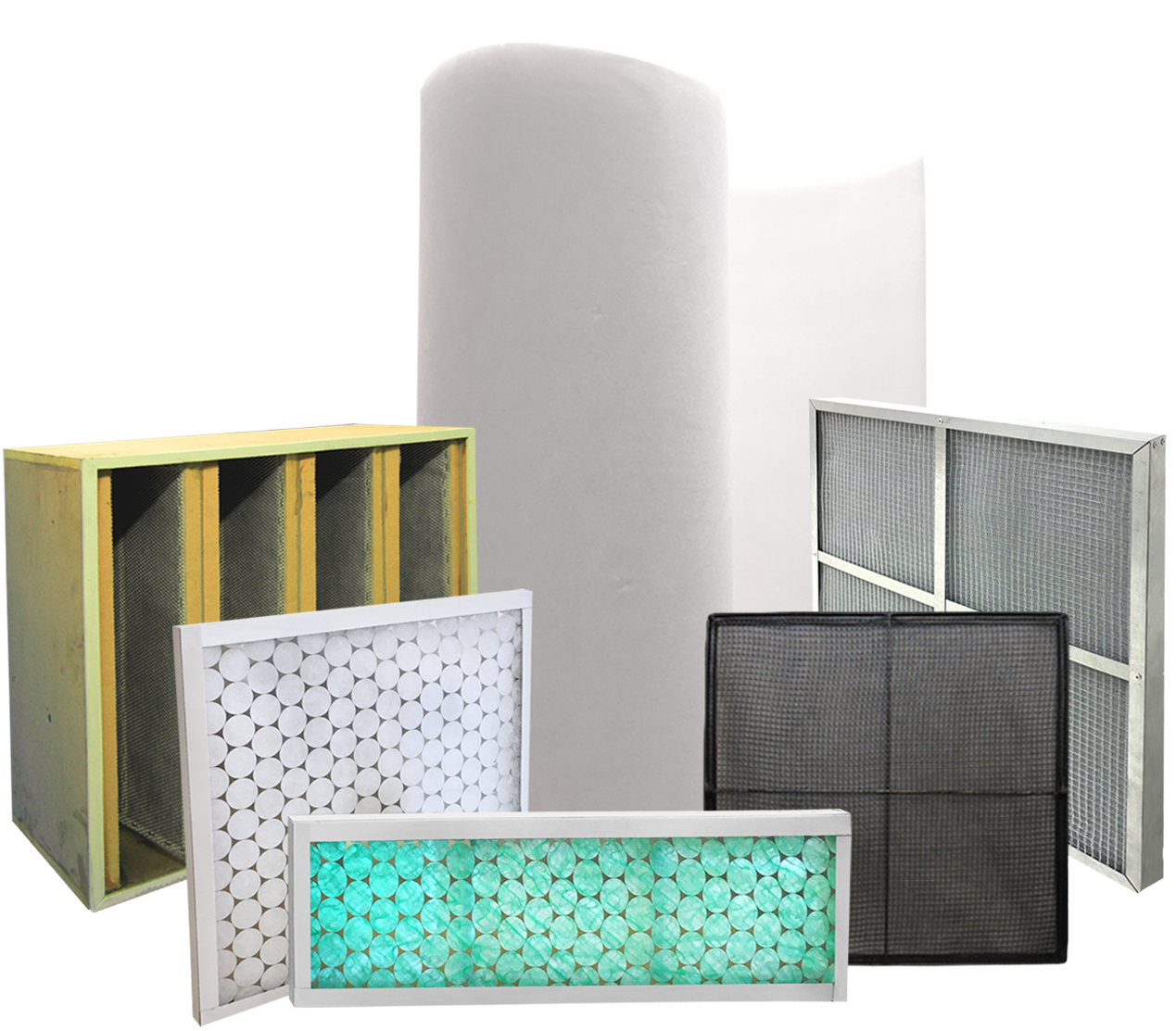

Get to know some of the main filter elements used in industrial filtration processes:

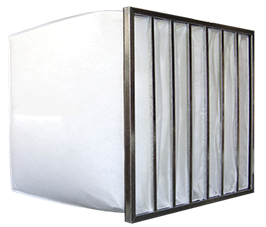

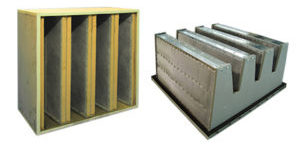

Multibag filters

The Multibag type air filters have their filtering medium in inert, non-toxic and non-carcinogenic synthetic microfibers. This filter has high accumulation capacity as a result of its large filtering area. They are recommended for high air flows, combined with large concentrations of particulates, such as: ventilation systems, exhaust and external air intakes; HVAC air conditioning systems; hospitals; pharmaceutical and food industries, as well as environments with a large amount of suspended particulates such as petrochemical, steel, transformation industries, among others.

Benefits

- Excellent dust holding capacity

- Long service life without affecting equipment operation

- Reduction in maintenance costs (fewer replacements)

- Low pressure drop, reducing power consumption

- Filtering area up to 15 times larger than face area

- No support mechanisms in operations on self-supporting filters

- Wide range of filtration efficiency

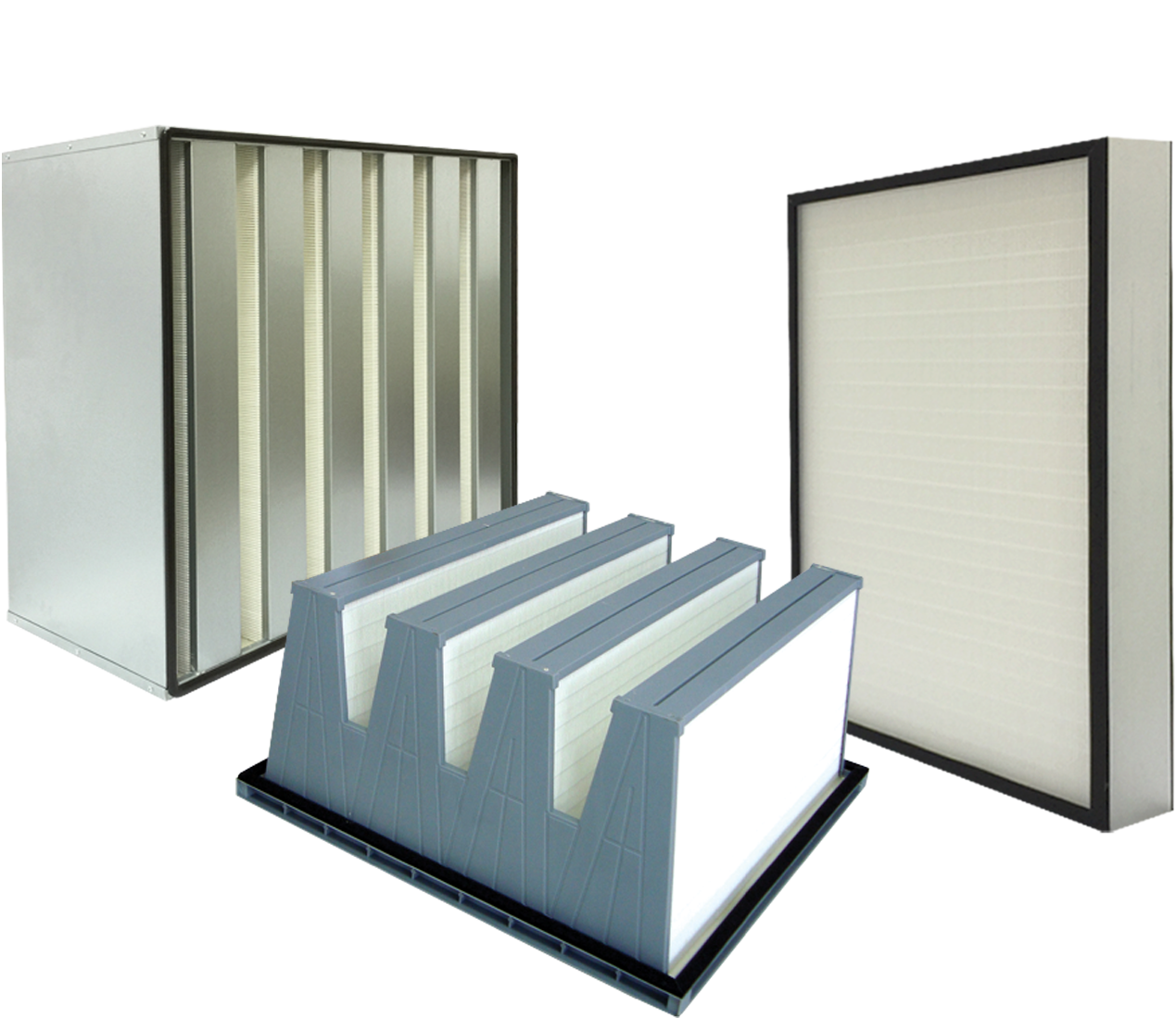

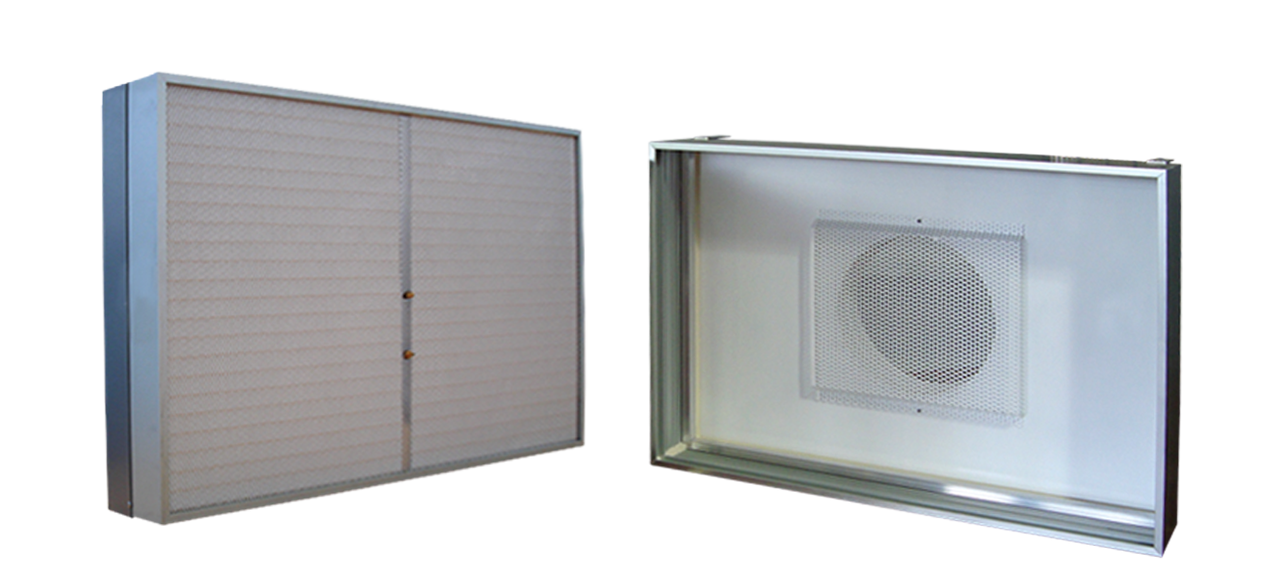

HEPA Absolute Filters

With a pleated glass microfiber filter element with a cord or resin separator, the HEPA Absolute Filters have an efficiency of up to 99,995% for 0,3µm particles, Class H14 (EN 1822). In addition, they feature highly efficient particle separation technology. They are mainly applicable in: air conditioning systems; clean rooms; ventilation and exhaust systems; microelectronic industries; chemical industries; food industries; medical; pharmaceutical; microbiology, laboratories, among others.

Benefits

- They are 100% leak tested

- Suitable for all types of applications where a high degree of air cleanliness is required

- Stable airflow and long life (with proper maintenance of pre-filters)

- mechanically stable

- Various types of frames and dimensions

- Can be supplied with rubber or gel seal

- Frame “knife” system when using gel

Activated Carbon Filters

With its filter medium in activated carbon granules (the type of activated carbon will depend on the application in which the filter will be used), Activated Carbon Filters are widely used in industrial processes, in order to perform air purification and attenuation of different odors, both organic and inorganic. Its typical applications are: return air conditioning installations, and renovation of external air in food industries, chemical industries, kitchens, hospitals, laboratories, among others.

Benefits

- Odor attenuation: body; fat; cooking odors; cigarette smoke; fumes in general

- Capture and attenuation of odors and gases harmful to health: solvents, pesticides, hydrocarbons, among others…

A Linter Filters has been working for 23 years offering a wide range of filters e equipment for air treatment.

Discover the entire line of products through our website or click on the link below request a commercial contact

![]()