Air filters and their applications

Why are they so used in industrial processes?

When it's about air treatment, there are different types of air filters available on the market, but when choosing the right filter for your company or industry, do you know how to identify the best filter for your needs?

Air filters are used in various processes and there is a specific type for each application.

Understand…

There are filters that attenuate unwanted odors (organic or inorganic); there are those that are used in air conditioning systems, preventing the spread of dust, fungi and other contaminants that cause damage to the health of people exposed in the place; in addition, there are also pre-filters that work together with the filters, increasing their durability, among many others.

Air filters can also help to reduce costs in your company in the medium and long term, because they drastically reduce machine downtimes for their replacement.

The benefits are therefore numerous and it depends a lot on the properties and applications of each one.

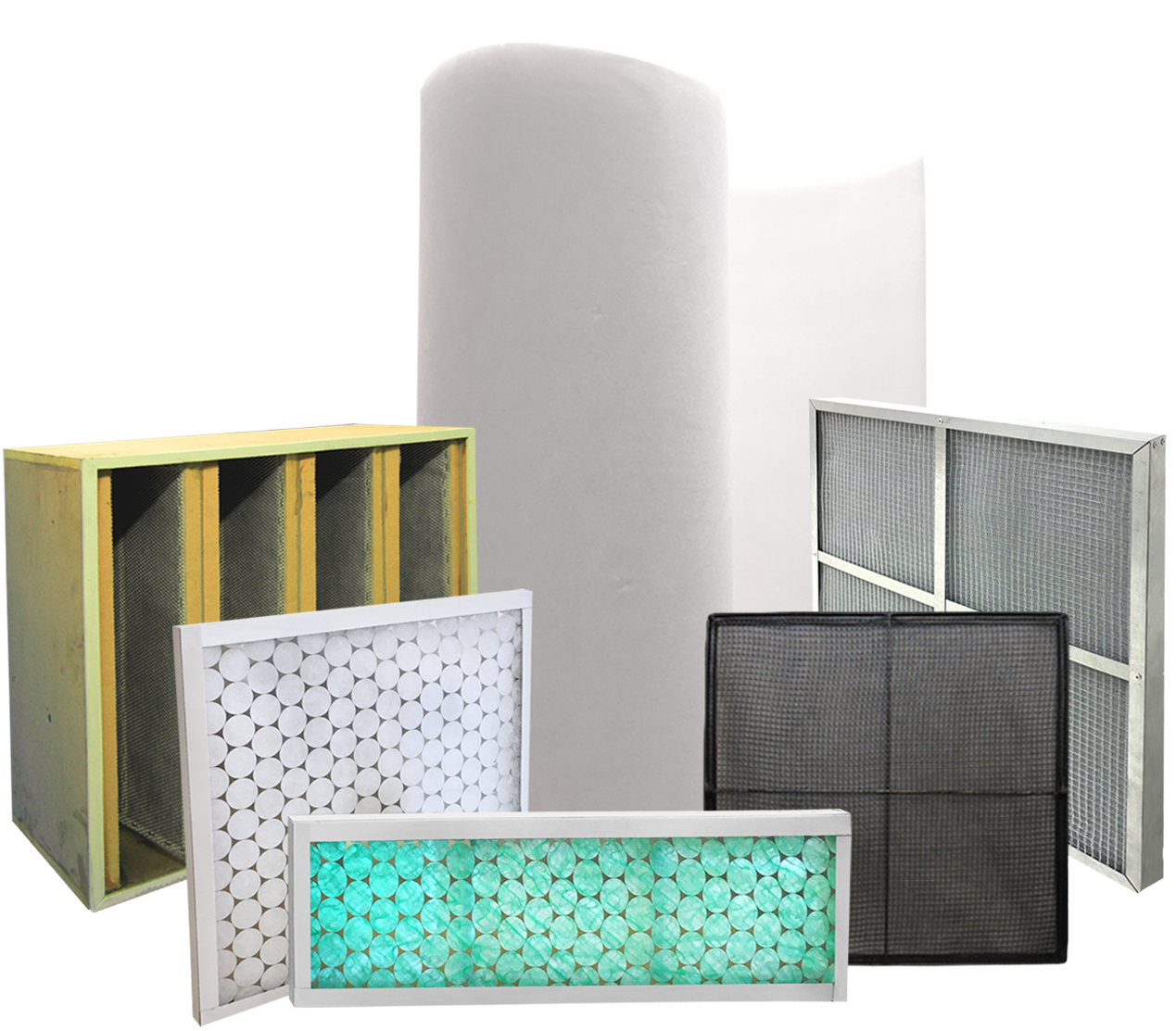

We have separated some of the most commercialized models to better explain their features, check out our list below and learn about their advantages and applications.

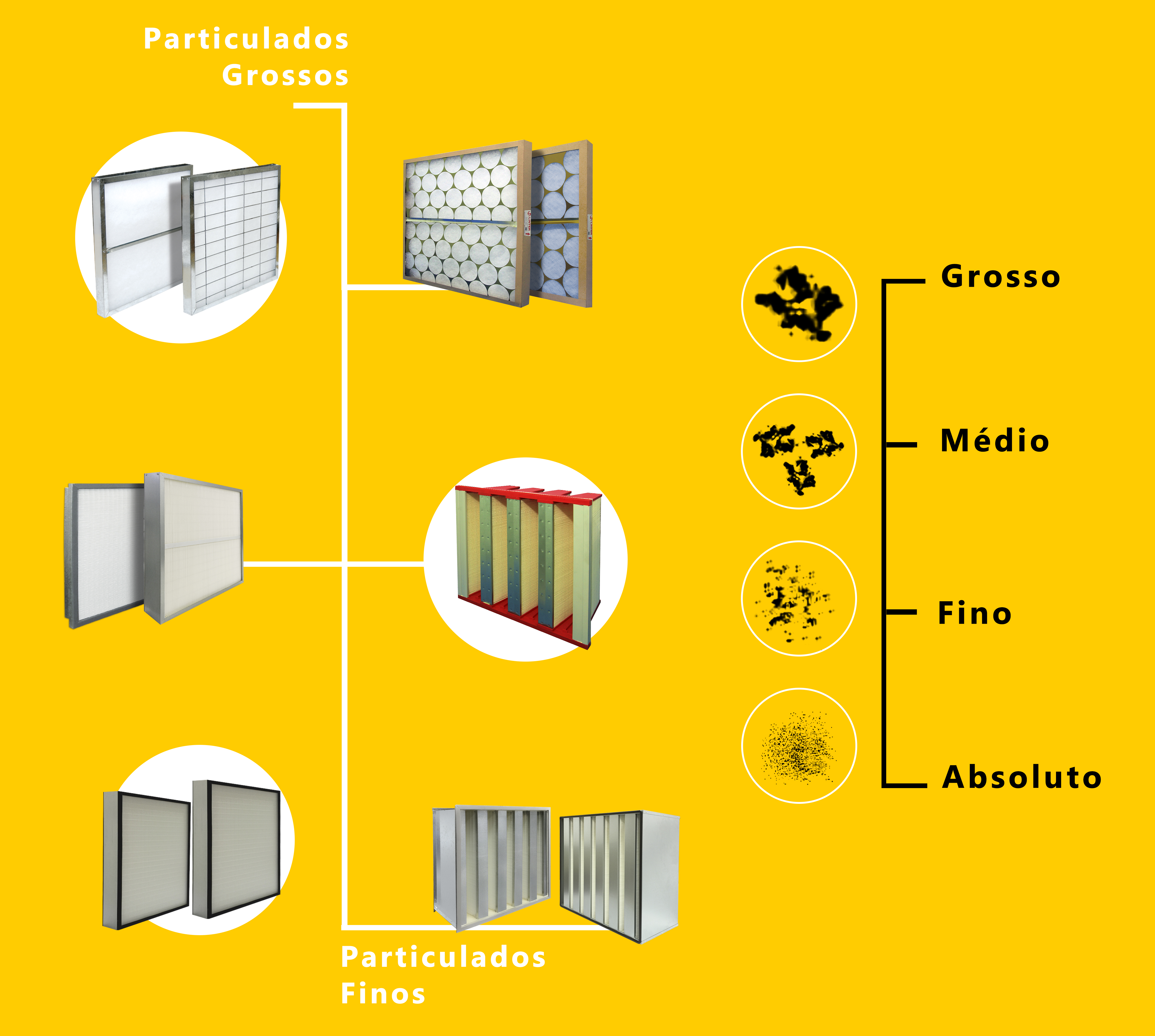

COARSE AND MEDIUM FILTERS

1 - Blanket Filters – Manufactured in galvanized steel sheet or stainless steel, with a support screen at the air outlet, its light construction makes the Porta Mantas a filter that is easy to handle, install and maintain.

Benefits

- Only the filter element is replaced, reducing waste generation

- Permanent structure, therefore lower maintenance cost

- More options when choosing the filter element

- Higher mechanical strength compared to disposable filters

Applications: are indicated for air filtration in general or for any air conditioning system, as well as pre-filters for high efficiency filters (fine filters).

2 - Disposable Flat Filters – Manufactured with a cardboard frame and perforated screen to support the filter element. They have a filter element made of fiberglass or synthetic mat, non-toxic and good dust accumulation capacity.

Benefits

- 100% combustible

- Great dimensional variety.

Applications: air conditioning installations, outdoor air intakes, spray booths and other applications that require coarse particulate protection.

FINE FILTERS

3 - Fine Filters – remove airborne contaminants such as: smoke, steam, pollen, soot, etc.

Benefits

- Long lifespan: Filtering area x longer service life

- Greater savings: Low pressure drop x maximum economy

- Rigid construction: Depths (50/75/100 mm) x easy installation

- Integral filter element: Prevents fiber migration

Applications: as final filters or pre-filter of absolute filters (HEPA / ULPA), in HVAC installations.

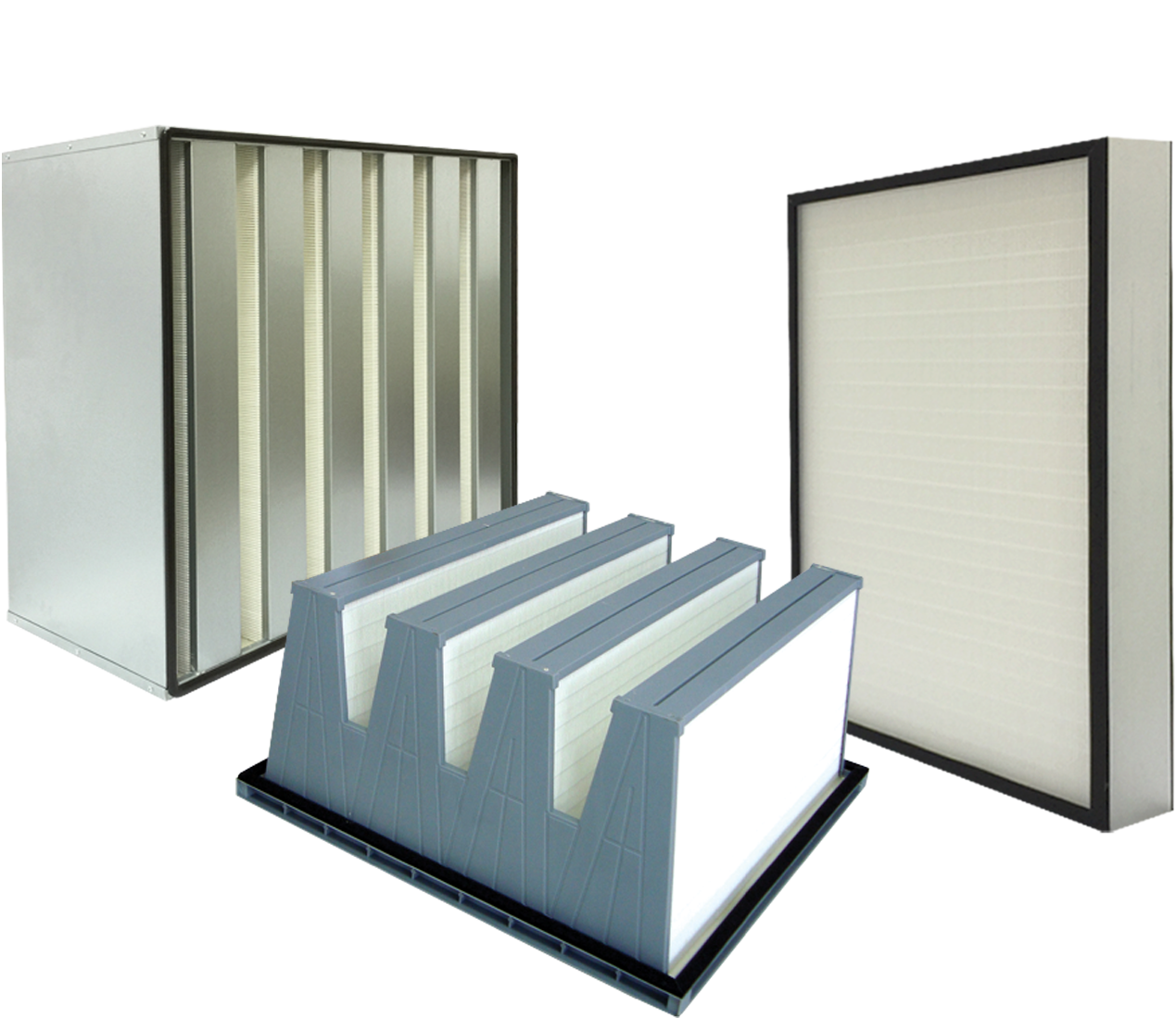

ABSOLUTE FILTERS

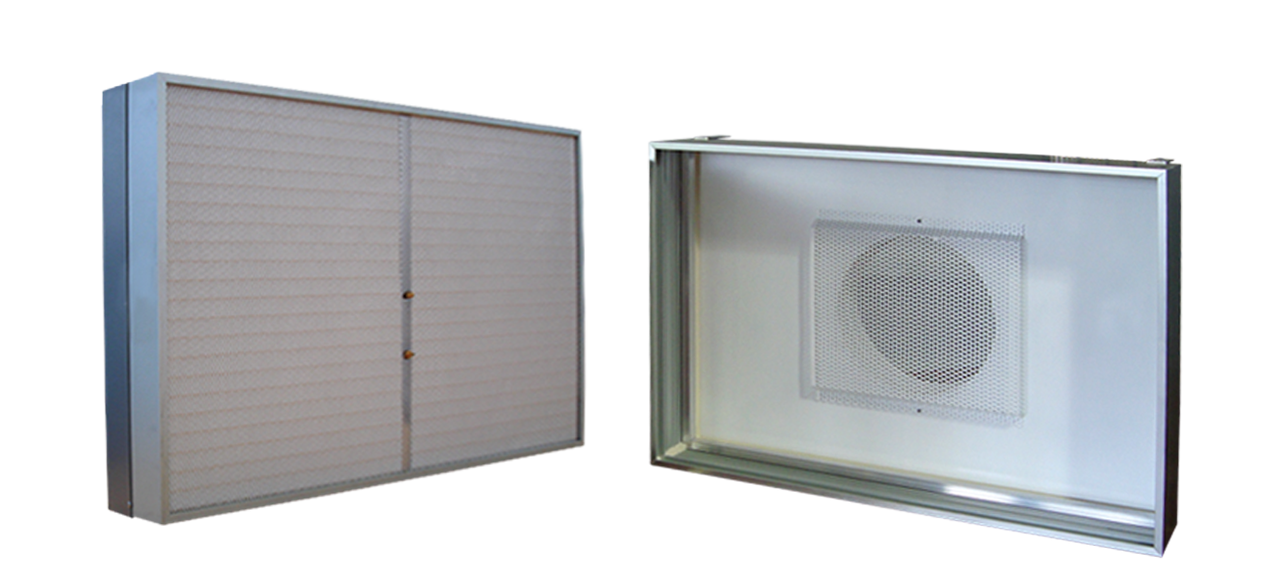

4 - HEPA Absolute Filters – have efficiency above 99,995% for 0,3µ particles, Class H14 (EN 1822). They are intended to protect people, equipment from contaminated particles. They are used in situations where high levels of air purity are required.

Benefits

- Suitable for all types of applications where a high degree of cleanliness is required

- Optimized speed distribution

- Stable airflow and long service life

- Leak-free guarantee

- mechanically stable

- Various types of frames and dimensions

- Can be supplied with rubber or gel seal

- “knife” system frame

Applications: typical applications can be found in: microelectronics, semiconductor manufacturing, medicine, chemistry, pharmacy, microbiology, laboratories and the food industry

OTHER

5 - Activated Carbon Filters – Used when there is a need to attenuate different odors (organic or inorganic), such as: body, cigarette, grease, solvent, pesticides, etc. A specific type of activated carbon is required for each application (always consult our technical department)

* It is important to have one or more pre-filters before applying carbon filters to avoid carbon contact with solid particles.

Applications: Return air conditioning installations, renewal of external air, adsorption of smoke odors (cigarettes, grease), adsorption of solvents in painting installations, adsorption of chemical gases (chlorine, hydrocarbons, etc.).