The Air Treatment Units, also known as UTA, are equipment that has the function of treating and recirculating the air in certain environments. The AHUs are part of the system of HVAC / HVAC: Heating, Ventilation and Air Conditioning, but they can also be used outside these systems, and in these cases they only provide filtration and ventilation for places that do not directly need air treatment (such as factory sheds).

Cleanroom AHUs remove air from the environment, promote filtration, and then return the air to the same environment safely, cleanly and free of contaminants.

This constant recirculation of air, in addition to filtering it, also supports the control of the temperature and relative humidity of the place.

Clean Rooms are controlled and fundamental environments for laboratories, pharmaceutical and food industries, as well as research institutes or places that demand extreme air quality. Controlling contaminants in the air prevents particles from directly interfering with or harming the processes performed by these companies.

The Air Treatment Units - UTA for clean rooms must have a contamination control system, pressurization and air conditioning unit with G4, F9 filter and HEPA filter (Absolute) with class H13 or H14 according to ABNT NBR 16401.

They are normally made of galvanized or stainless steel structure.idable and aluminum. They are usually modular equipment that allow variation in their assembly form and size. Inside the AHU's are their functional elements.

Main Functional Elements of an Air Handling Unit

Ventilador

Used to move the air, the Treatment Units can contain one or more fans inside, this can vary according to the project and size of the AHU used. There are still some variations in the use of fans within this system, which can be installed at the AHU outlet or in the insufflation process.

Cooling and Heating Elements

Some elements are used that allow the control of the air temperature. Steam or electrical resistance is used for heating and chilled water or direct expansion for cooling (refrigeration). The method adopted will depend mainly on the need for the application.

Filter Elements

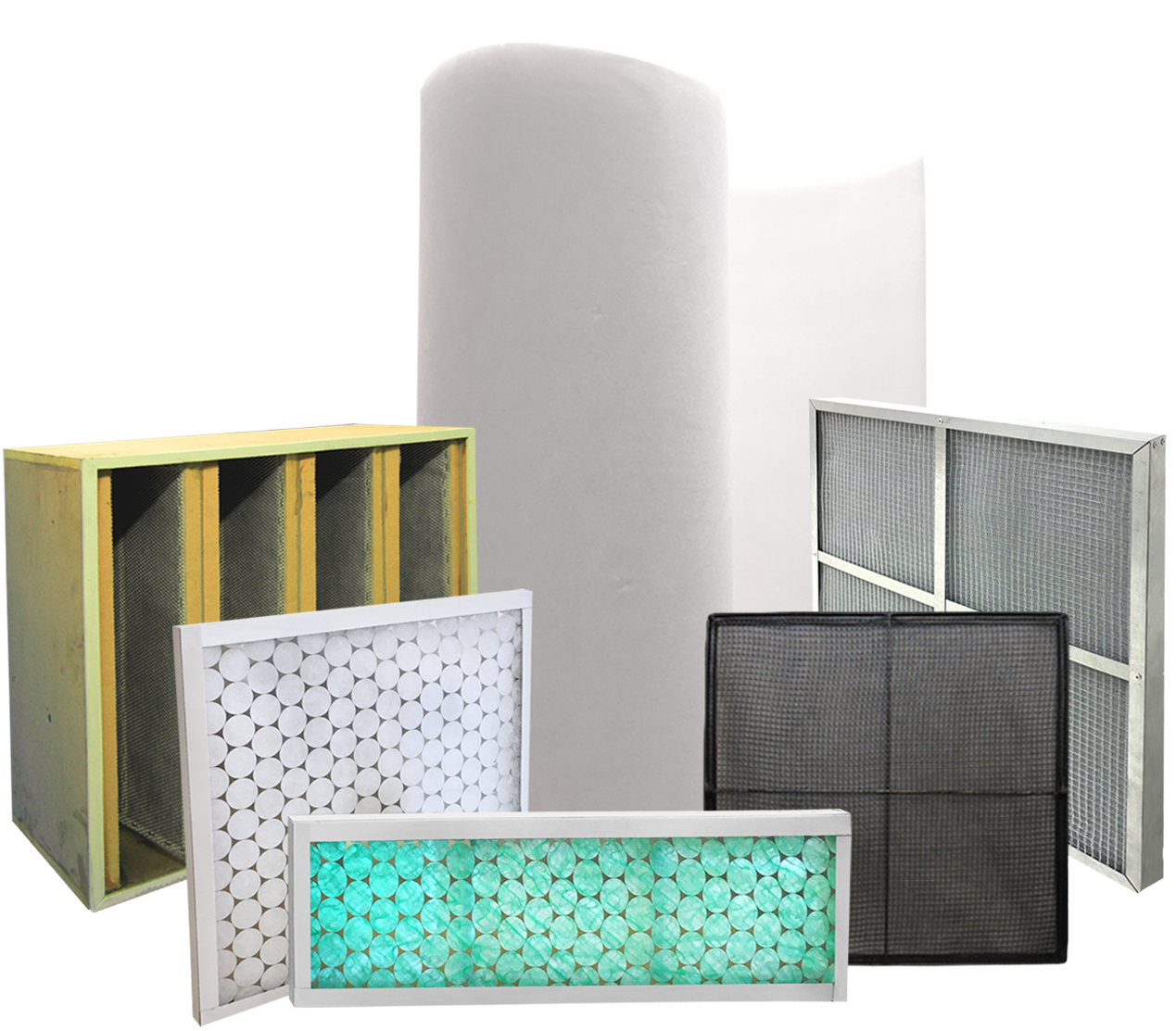

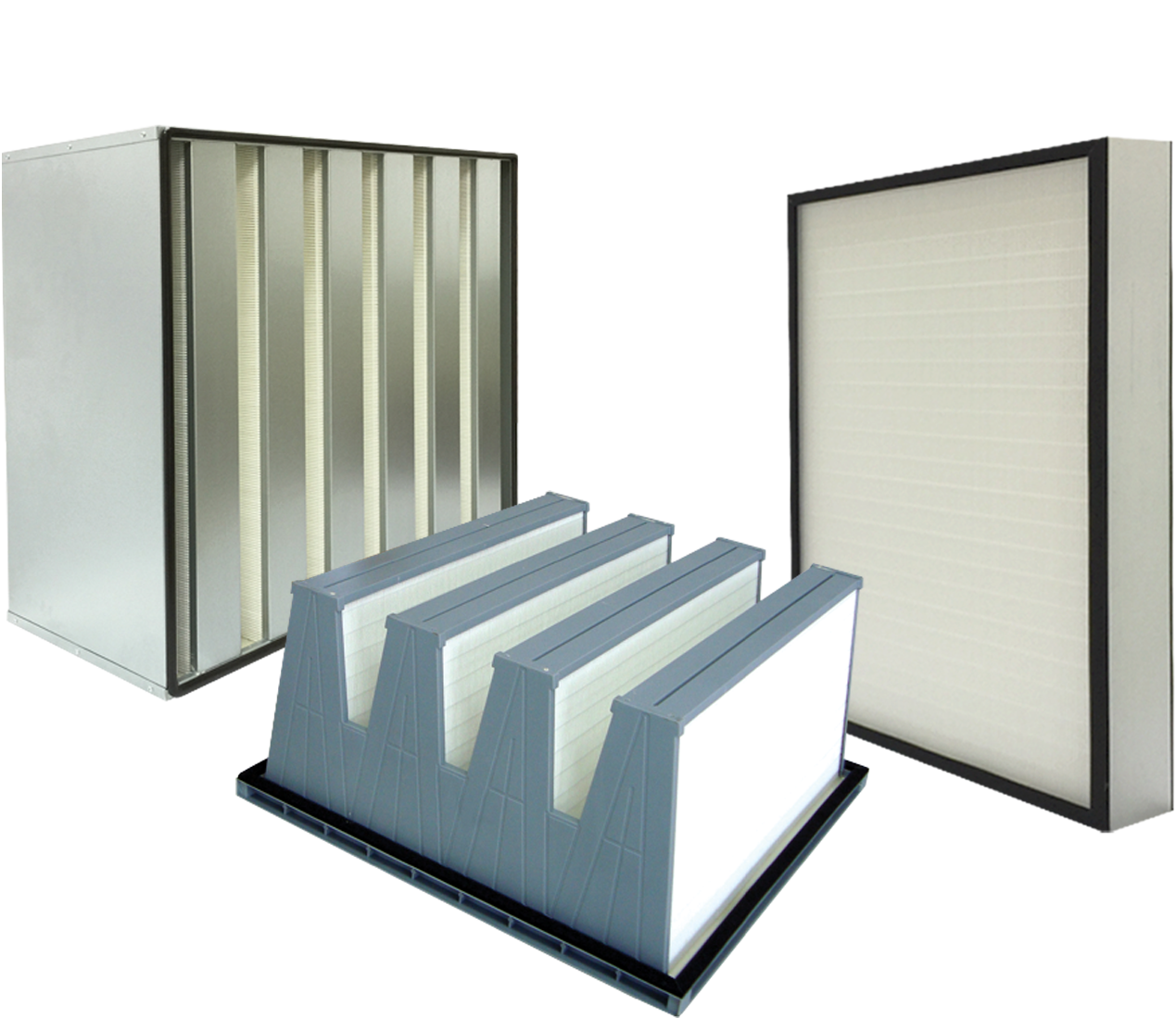

The use of filters and pre-filters in the AHUs is what guarantees air free of impurities. You Coarse Filters are installed at the air inlet, so that the entire system is preserved from possible contaminants. These filters filter larger particles, preventing them from contaminating the entire system. In addition, pre-filtration extends the life of fine and absolute filters.

Os Fine Filters e HEPA absolutes they are used after the fan, promoting better air quality for use in clean rooms, where a high degree of purity of this element is essential, to avoid contamination in the place.

Changing the Filters

If saturated, the air filters can compromise the effectiveness of the entire system, even causing its contamination. Therefore, there is a need for continuous monitoring to ensure that the exchange of air filters is carried out within the correct period.

noise attenuators

Some AHUs may make noises due to their fan system. To prevent the propagation of these sounds, attenuators are used.

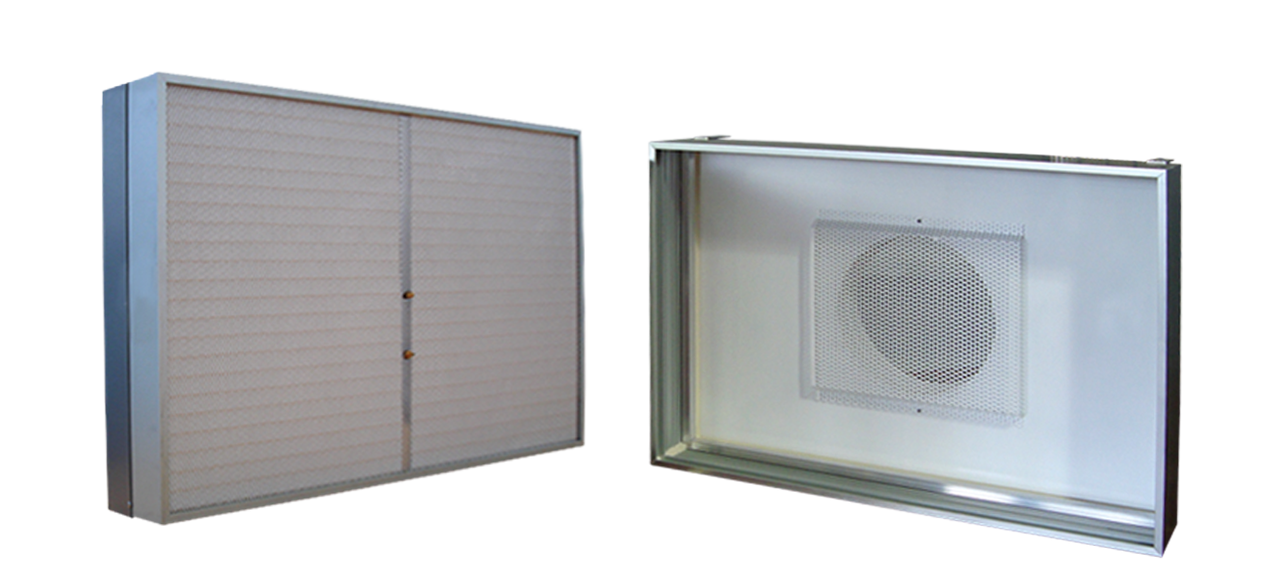

Linter Filters, in addition to manufacturing filters, also manufactures equipment for air conditioning systems such as; Filter Boxes with 1, 2 or 3 filtering stages, Filter Panels for flat filters and wedges, Fan Filter Unit GII, Terminal Boxes , Compact Filtration and Ventilation Units e Permanent Filter Boxes ou Disposable for ceilings, filtering plenums and ceiling.

Now that you know a lot about an Air Treatment Unit – UTA, how about getting in touch with Linter Filters that manufactures Air Treatment Units as well as having a complete line with all the Filters needed for an AHU.

Click the button below 👇🏼 and request more information.

Hey! I want to talk.