Air Exhaust System

for compounding pharmacies

In compounding pharmacies, the risk of contamination is imminent and relatively high due to the amount of formulas that are developed and chemical products that are handled daily. This can cause several damages to the health of professionals in the area.

Some basic care is therefore necessary and is part of good practice, so that these places work safely and without major problems.

The integrity and effectiveness of the products, and above all the health and protection of people, is what is at stake. Understand…

Manipulation Pharmacy

Unlike drugstores, commonly also called pharmacy (place where medicines are only sold). The compounding pharmacies are more complex environments, because inside them, different formulas and substances of chemical origin are manipulated; minerals; synthetics; volatile, among others… Which may or may not be toxic and harmful to health.

Due to the large quantity and diversity of products that are handled there (so that they become the medication ordered by the patient). The places where pharmaceuticals are developed have materials in suspension inside, increasing even more the risks in these sectors of activity… Therefore, air treatment is an indispensable protection system in these places!

air treatment

Products in compounding pharmacies are the result of chemical and biological reactions, of substances that were combined and dosed with the purpose of transforming these inputs into usable formulas for patients. With the continuous handling of these materials, waste is generated and is suspended in the air.

In these processes, liquid particles (such as gases and vapours) that are hazardous to health are released. As much as solid particles and chemical dusts are also given off. All these materials are harmful, both for local professionals and for the environment itself. The inhalation of these particles can cause several health damages, including serious diseases.

So these particles must be kept away from the formulas being prepared. As well as the inputs, under the risk of contaminating other materials, which in addition to bringing financial losses, may harm third parties, that is, the final consumer, in case of contamination of products.

So these particles must be kept away from the formulas being prepared. As well as the inputs, under the risk of contaminating other materials, which in addition to bringing financial losses, may harm third parties, that is, the final consumer, in case of contamination of products.

Insufflation and Exhaustion System as necessary care…

It is precisely to avoid this type of critical situation that air treatment is essential in these sectors…

The removal of air contaminated by particles, and the injection of clean air into the environment brings safety to the place!

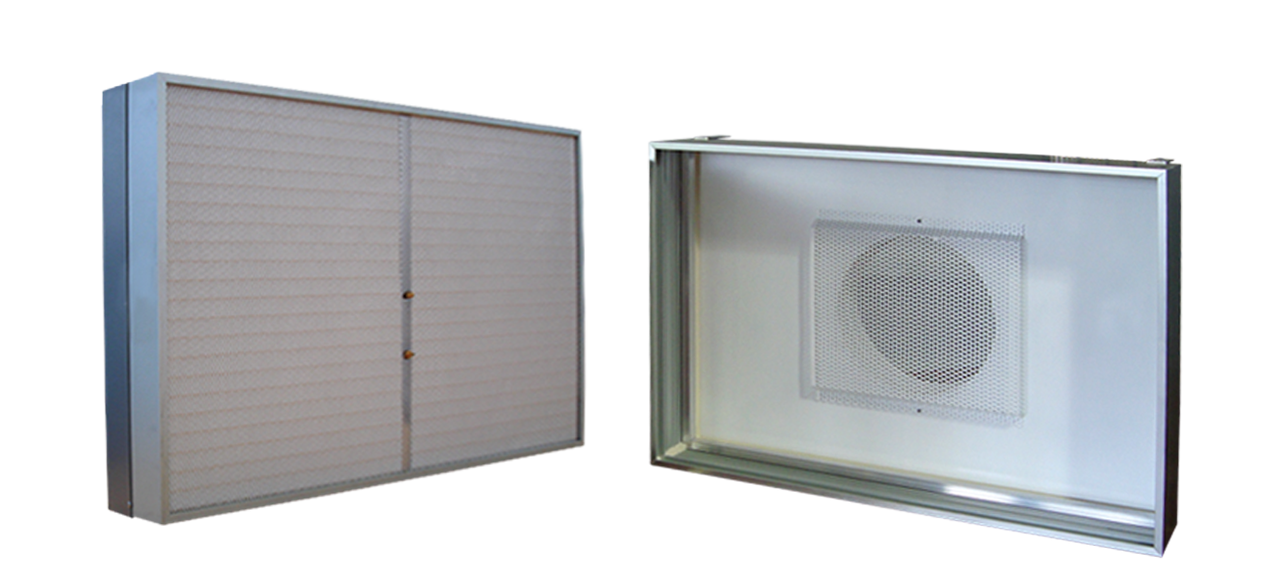

The exhaust system performs the removal, while the clean air is deposited again by the local supply system.

In compounding pharmacies, the exhaust system is a way of controlling the renewal rate and indoor air quality. But it's thanks to air filter, that the air becomes clean and reliable.

Air Filters in Exhaust and Insufflation Systems

Some processes, as in the case of handling eye drops or similar cases (where the handled product requires a very high degree of preservation), before being deposited in the environment, the air needs to go through a filtering process in order to guarantee the quality of the product. same.

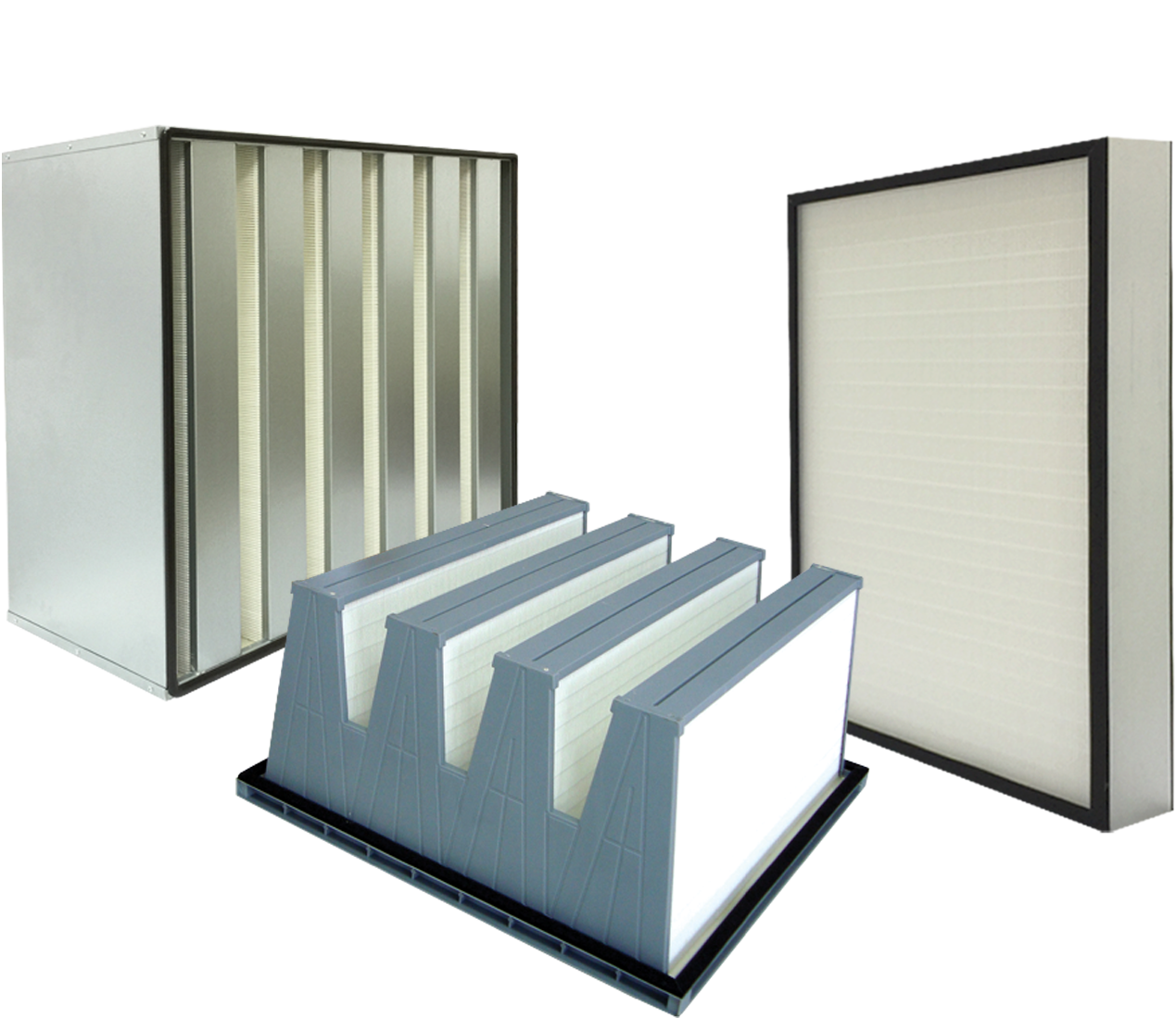

Fine Filters e HEPA ensure that the quality of the incoming air is absolutely clean.

In the same way and equally important, depending on the type of process carried out in compounding pharmacies, when the waste generated releases fragments that are considered hostile, it is necessary to carry out pretreatment of the air before discharging it.

So, when removing contaminated air from the pharmaceutical environment, when it is returned to the atmosphere, the air also needs to be filtered, passing through the HEPA filters to avoid environmental contamination (which is even liable to a fine, for causing damage to the environment).

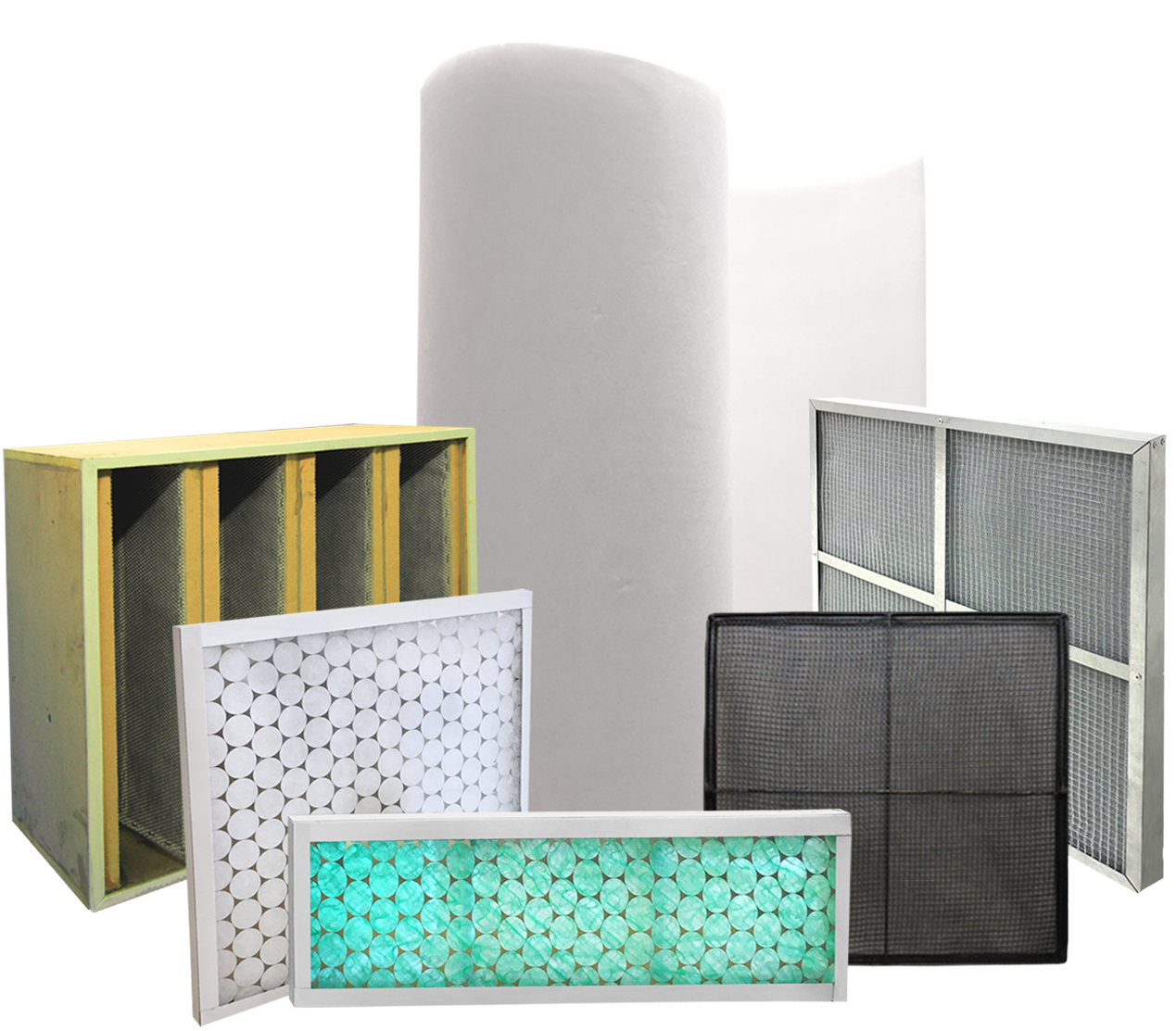

Os air filters they carry out filtering by blocking various contaminants, from particles and gases from the processes carried out, to fungi, mites, viruses and bacteria that can contaminate and cause damage to people, products and the environment.

There are several filters, each one serving a filtering class and being specific to a particular application. But above all within environments such as compounding pharmacies, Fine Filters e Hepa absolutes are widely used because they meet the level of classification that these places need.

It is also common for these pharmacological environments to use air pressure control systems. Which can be both positive and negative. This will depend on the processes that are carried out.

The pressurization system also works as a tool to control safety in the case of handling sterile waste and toxic substances.

Linter has filters for air exhaust and ventilation systems.

Click here and learn about our successful cases 👉🏻 Success Cases

Or consult one of our representatives and request a business contact 👉🏻 Business Contact