Hospitals are places with a high concentration of viruses, fungi, bacteria and other contaminants present in the air. This is due to the large number of sick people who circulate in wards, receptions, reserved or open wards and other hospital facilities.

For the vast majority of hospitals, it is a great challenge to maintain air quality and offer a safe system of maximum protection in order to avoid contamination in professionals, patients and their companions.

Air Conditioning Systems have as main objective to offer thermal comfort to their users and never serve as a vector of transmission and contamination by air. When maintenance is not carried out, and consequently the periodic exchange of filters, the system can greatly harm the health of the occupants. There is even a law known as PMOC, which requires constant maintenance and analysis with central air conditioning to avoid possible respiratory diseases in closed places.

Linter Filters is one of the largest and leading manufacturers of filters for air conditioning systems. Manufactures and sells the main filters indicated for central air conditioning in hospitals and other market segments.

Discover below the main filters used in air conditioning systems and their characteristics:

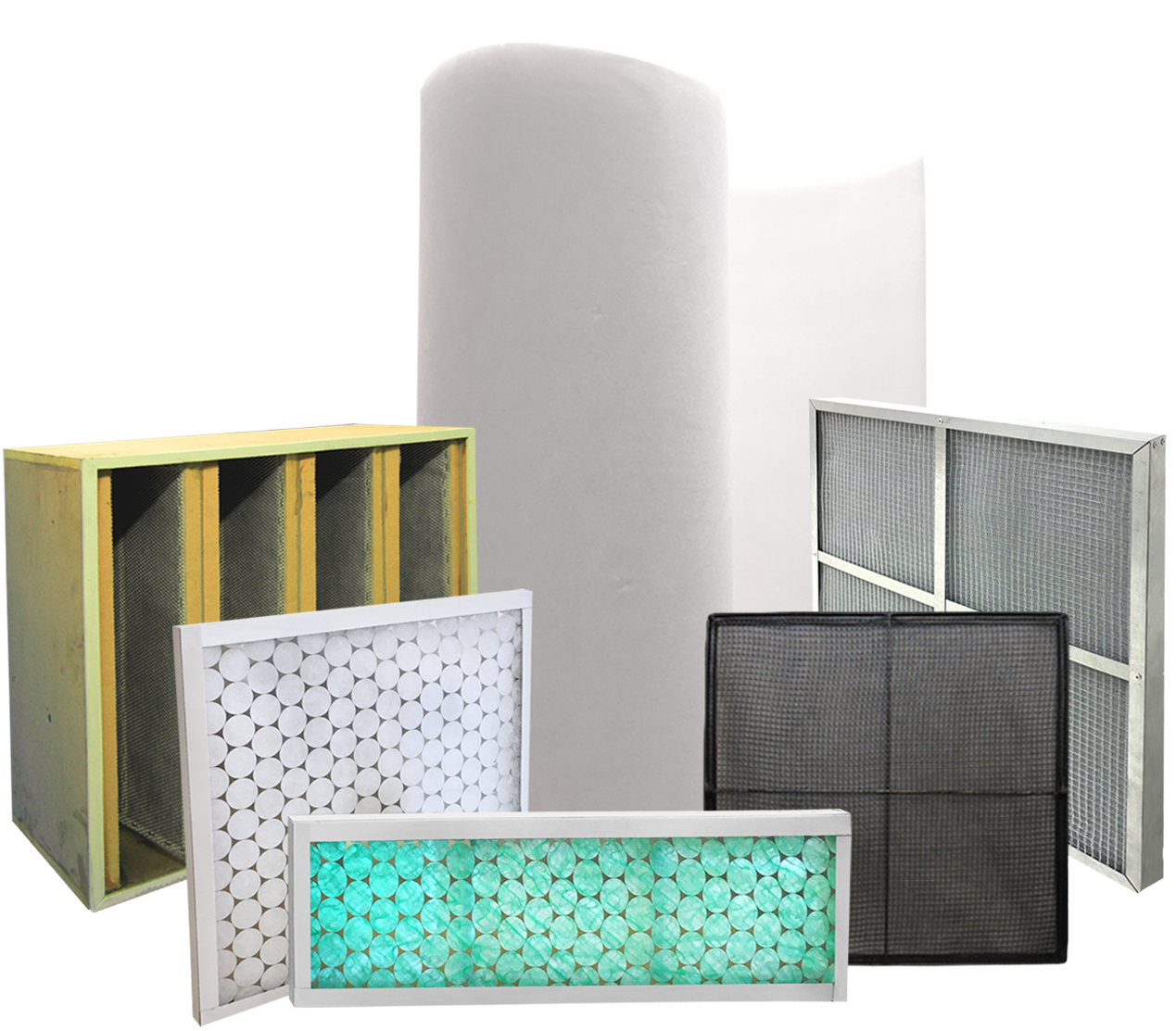

- Synthetic Fiber Air Filter Blankets – It has different weights and is used as pre-filters for air conditioning systems. With G4 filtration class (ABNT), it filters larger particles (Coarse Filters) in addition to prolonging the useful life of fine and absolute filters (HEPA).

- Embossed Filters ou Blanket Holder – Depending on the air conditioning system, the pre-filter used may be a flat, boxed filter or blanket holder.

Filter holders, known as permanent filters, only change the filter element, so the maintenance cost is much lower. - Pleated Filters - They are produced in zig-zag or accordion format, they are made of pleated synthetic fiber that are characterized by high filtering power.

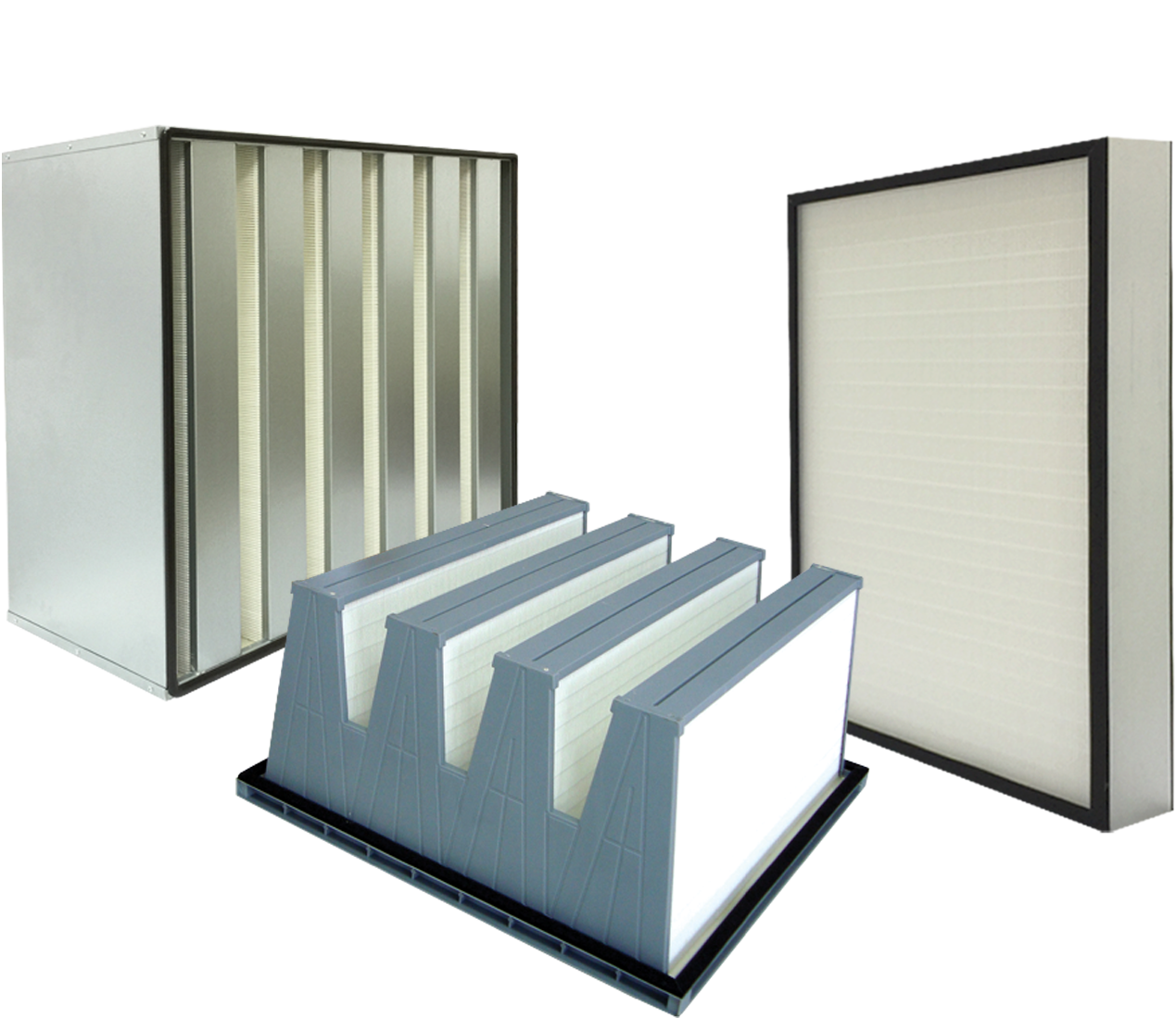

- Multibag filters – They are made of non-carcinogenic and non-toxic microfibers. Filters retain particles gradually along their filtering levels. In addition to having excellent dust holding capacity, they have a wide range of filtering efficiency (G3:F9).

- Fine Filters – They are applied as final filters or pre-filter for Hepa filters. They have filtering class F7, F8 or F9.

- Hepa filter – Absolute filters retain particulates down to 0,3µ. The Hepa Filter is the most suitable when we talk about air quality. Its application is mainly indicated in places where there is a need for high levels of air purity, especially in operating rooms and clean rooms.

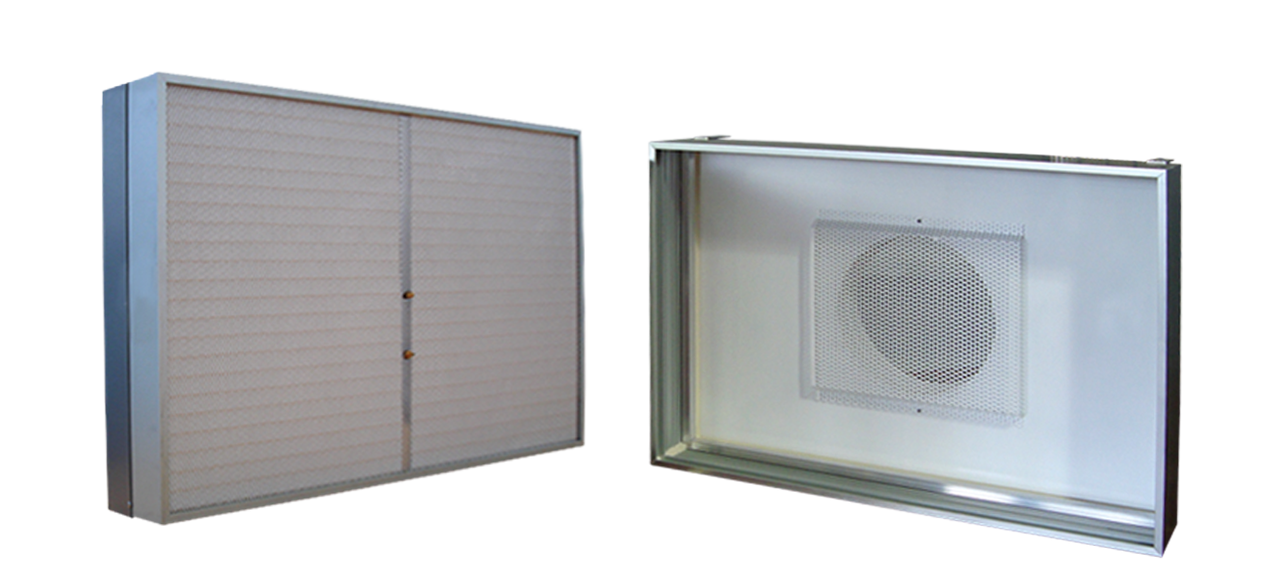

Linter Filters, in addition to manufacturing filters, also manufactures equipment for air conditioning systems such as; Filter Boxes with 1, 2 or 3 filtering stages, Filter Panels for flat filters and wedges, Fan Filter Unit GII, Terminal Boxes , Compact Filtration and Ventilation Units e Permanent Filter Boxes ou Disposable for ceilings, filtering plenums and ceiling.

Contact Linter Filters and ask for help from our engineers specialized in air conditioning systems.

Click the button below 👇🏼 and request more information.

Hey! I want to talk.